CNC routing is a powerful tool for shaping and cutting materials, and 5052 aluminum is one of the most popular materials for CNC machining due to its excellent mechanical properties, corrosion resistance, and ease of加工. In this guide, we will walk you through the process of CNC routing 5052 aluminum, covering everything from material preparation to finishing touches. This guide is designed to be easy to follow, ensuring that both beginners and experienced CNC operators can benefit from it.

Understanding 5052 Aluminum

Before diving into the CNC routing process, it’s essential to understand the material you’re working with. 5052 aluminum is a widely used alloy known for its high strength-to-weight ratio, good corrosion resistance, and excellent formability. It is commonly used in industries such as aerospace, marine, and automotive due to its durability and lightweight properties.

- Key Properties of 5052 Aluminum:

- High strength and durability

- Excellent corrosion resistance, especially in marine environments

- Good thermal and electrical conductivity

- Moderate formability and machinability

Understanding these properties will help you make informed decisions during the CNC routing process.

Preparing for CNC Routing

Proper preparation is crucial for achieving accurate and high-quality results in CNC routing. Here are the steps to prepare for your project:

-

Material Selection:

- Ensure you have the correct grade of aluminum (5052) for your project.

- Check the thickness and dimensions of the aluminum sheet to match your design requirements.

-

Design and Programming:

- Use CAD software to create your design. Tools like AutoCAD, SolidWorks, or Fusion 360 are commonly used for CNC machining.

- Convert your design into CNC-compatible G-code using CAM software. G-code is the programming language that instructs the CNC machine on how to move and cut the material1.

-

Tool Selection:

- Choose the right cutting tools for 5052 aluminum. High-speed steel (HSS) or carbide tools are recommended for aluminum machining.

- Select the appropriate bit size and shape based on your design requirements.

-

Machine Setup:

- Secure the aluminum sheet to the CNC machine bed using clamps or vacuum fixtures to prevent movement during machining.

- Calibrate the machine to ensure accurate tool positioning.

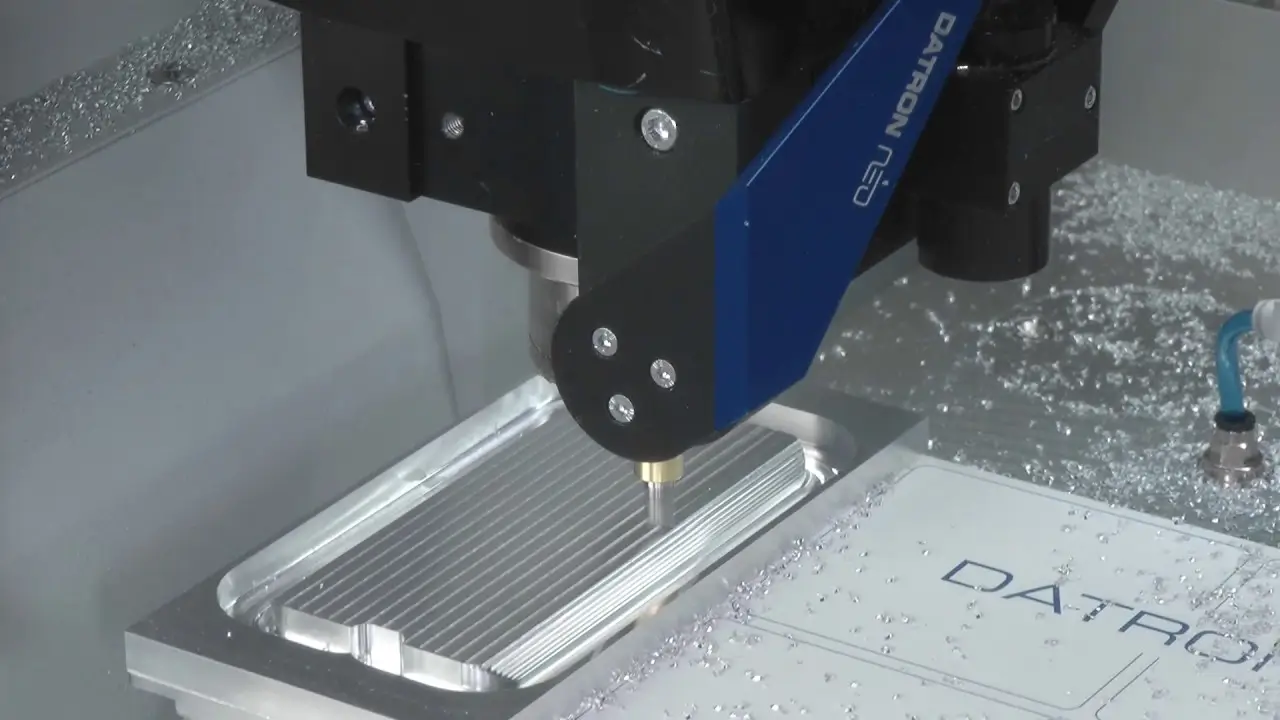

CNC Routing Process

Once your machine is set up and programmed, you can begin the CNC routing process. Here’s a step-by-step breakdown:

-

Step 1: Initial Setup

- Load the G-code program into your CNC machine.

- Perform a dry run (a test run without cutting) to ensure the tool path is correct and there are no errors in the program.

-

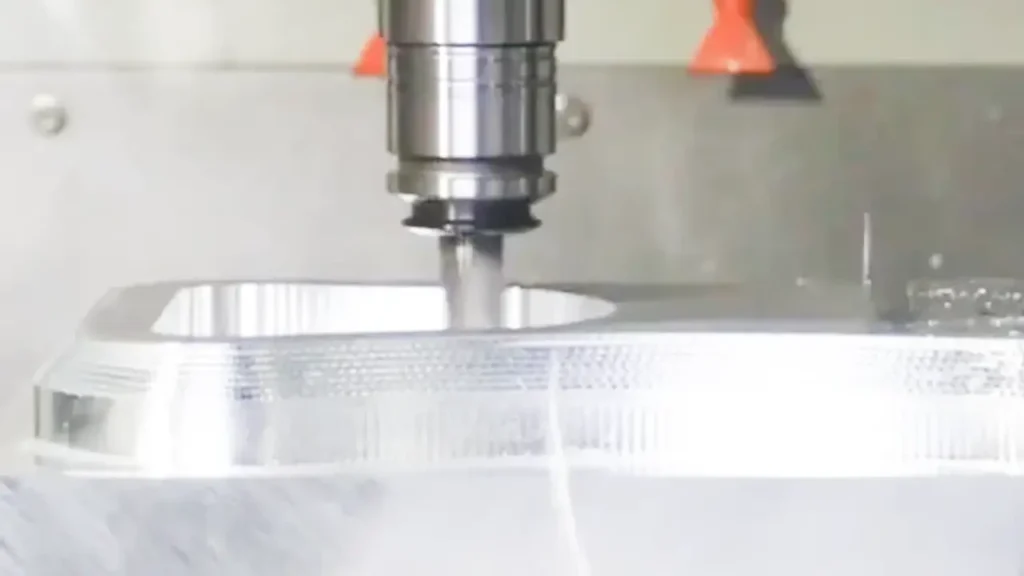

Step 2: Cutting

- Start the machine and begin cutting the aluminum. The CNC machine will follow the programmed G-code to shape the material according to your design.

- Monitor the machine for any unusual sounds or vibrations, which could indicate a problem with the tool or the material.

-

Step 3: Finishing Touches

- After the main cutting process, inspect the part for any rough edges or imperfections.

- Use sandpaper or a deburring tool to smooth out the edges and achieve a polished finish.

Tips for Successful CNC Routing of 5052 Aluminum

To ensure the best results when CNC routing 5052 aluminum, consider the following tips:

-

Coolant Usage:

- Aluminum generates a lot of heat during machining, so it’s important to use coolant to prevent overheating and maintain tool longevity.

- Use flood coolant or mist coolant to keep the cutting area cool and clean.

-

Feed Rate and Speed:

- Adjust the feed rate and spindle speed according to the tool and material properties. For 5052 aluminum, a moderate feed rate and high spindle speed are typically recommended.

- Refer to tool manufacturer guidelines for optimal settings.

-

Tool Maintenance:

- Regularly inspect and replace dull or worn tools to maintain cutting accuracy and surface finish.

- Use high-quality tools to ensure consistent results.

-

Material Handling:

- Handle the aluminum sheet carefully to avoid scratching or denting the surface before and after machining.

- Store the material in a clean, dry environment to prevent corrosion.

Common Issues and Troubleshooting

Even with careful preparation, some issues may arise during the CNC routing process. Here are some common problems and solutions:

-

Issue: Tool Breakage

- Solution: Ensure the tool is properly secured in the machine and that the feed rate and spindle speed are set correctly. Use high-quality tools designed for aluminum machining.

-

Issue: Poor Surface Finish

- Solution: Check the tool condition and ensure the coolant is being applied correctly. Adjust the feed rate and spindle speed if necessary.

-

Issue: Material Warping

- Solution: Use clamps or vacuum fixtures to secure the material firmly to the machine bed. Avoid overheating the material by using adequate coolant.

Applications of CNC Routed 5052 Aluminum

5052 aluminum is versatile and can be used in a wide range of applications. Some common uses include:

- Aerospace Components: Due to its high strength-to-weight ratio, 5052 aluminum is ideal for aircraft parts.

- Marine Equipment: Its corrosion resistance makes it suitable for boat parts and marine hardware.

- Automotive Parts: Used in car bodies, frames, and other structural components.

- Architectural Panels: CNC routed aluminum panels are commonly used in building facades and interior designs.

Conclusion

CNC routing of 5052 aluminum is a precise and efficient process that requires careful preparation and attention to detail. By following the steps outlined in this guide, you can achieve high-quality results and ensure the longevity of your CNC machined parts. Remember to always prioritize safety, maintain your equipment, and choose the right tools for the job. With practice and experience, you’ll master the art of CNC routing and unlock the full potential of 5052 aluminum for your projects.