In today’s rapidly evolving manufacturing landscape, specialized services like aluminum CNC machining have emerged as game-changers for businesses across various sectors. Whether you’re involved in the automotive, aerospace, electronics, or medical industry, the benefits of leveraging aluminum CNC services are significant and multifaceted. This article aims to delve deep into these benefits and explain why opting for a specialized aluminum machining service can be a strategic move for your business.

Understanding Aluminum CNC Machining

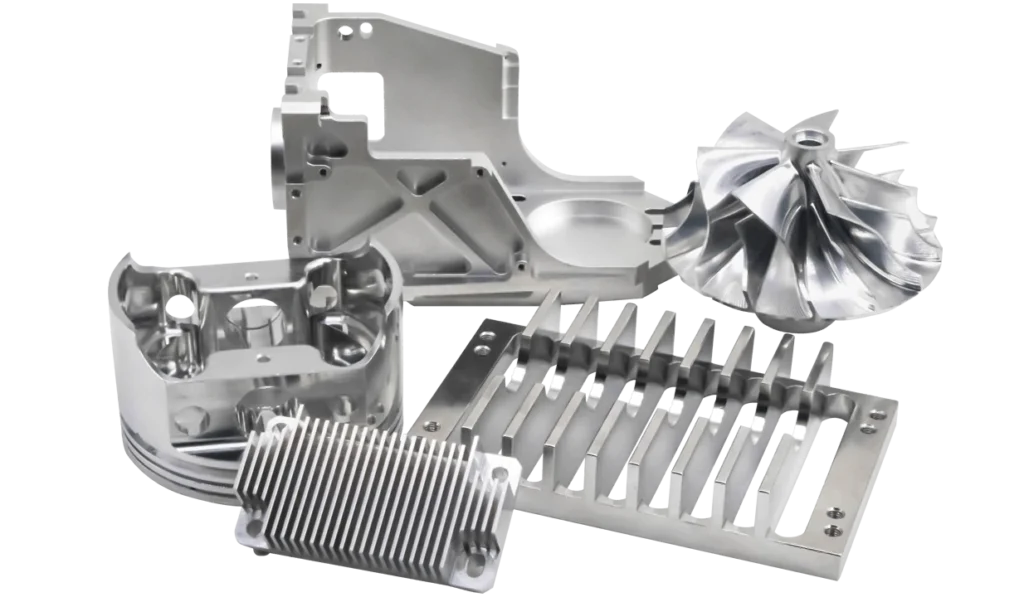

Before diving into the benefits, it’s essential to grasp what aluminum CNC machining entails. CNC, or Computer Numerical Control, machining involves using computers to control machine tools. In the context of aluminum, CNC machining refers to the precise cutting, shaping, and designing of aluminum parts using this advanced technology.

The Process

The process of aluminum CNC machining begins with a detailed design phase using computer-aided design (CAD) software. This software allows engineers to create intricate designs that can be precisely executed by CNC machines. Once the design is finalized, it is converted into a language known as G-code, which is the standard language CNC machines understand. The machine then uses this code to guide various tools in cutting and shaping the aluminum to match the exact design specifications.

The precision of this process allows for the creation of complex geometries and tight tolerances that are often required in high-performance applications. Additionally, the automation involved reduces human error, ensuring consistency and repeatability in large production runs. This capability is particularly beneficial for industries that demand high accuracy and reliability.

Why Aluminum?

Aluminum is a preferred material for many industries for several reasons. Its lightweight nature makes it ideal for applications where reducing weight is crucial, such as in the aerospace and automotive sectors. Despite its lightness, aluminum offers excellent durability and strength, making it suitable for parts that require robustness and longevity.

Moreover, aluminum’s resistance to corrosion is a significant advantage in environments that are prone to moisture and harsh conditions. It is also highly recyclable, which aligns with the growing emphasis on sustainability and environmentally friendly manufacturing processes. These attributes make aluminum an attractive choice for businesses looking to balance performance with environmental responsibility.

Historical Context of Aluminum CNC Machining

The journey of aluminum in manufacturing has seen significant evolution over the decades. Initially, aluminum was considered a luxury material due to the complexities involved in its extraction and processing. However, technological advancements have made it more accessible and affordable. The introduction of CNC machining revolutionized the use of aluminum by enhancing its manufacturability and expanding its applications across various industries.

This evolution was driven by the need for more efficient and precise manufacturing techniques. As industries demanded higher performance and tighter tolerances, CNC machining provided the solution by offering unparalleled precision and repeatability. Understanding this historical context highlights the transformative impact of aluminum CNC machining on modern manufacturing practices.

Key Benefits of Aluminum CNC Services

Leveraging aluminum CNC services offers a range of advantages that can significantly enhance your manufacturing operations. From precision and accuracy to cost-effectiveness and versatility, these services provide a comprehensive solution for businesses seeking to optimize their production processes.

Precision and Accuracy

One of the standout advantages of using aluminum CNC services is the level of precision and accuracy it offers. Traditional machining methods can leave room for errors, but CNC machining is computer-controlled, which minimizes human error. This precision is crucial for industries where even the slightest deviation can have significant consequences.

The ability to maintain consistent quality across large production runs is another critical benefit. CNC machines can replicate the same design with minimal variation, ensuring that each part meets the exact specifications. This consistency is vital in sectors like aerospace and medical, where component failure is not an option.

Furthermore, CNC machining allows for the creation of complex geometries that would be challenging or impossible with manual methods. This capability opens up new possibilities for innovation and design, enabling companies to push the boundaries of what is possible in their products.

Efficiency and Speed

CNC machines can operate continuously without breaks, which significantly boosts production rates. This efficiency means you can get more parts produced in less time compared to traditional methods. For businesses looking to scale up production, this speed is invaluable.

The automation of CNC machining also reduces the need for extensive manual labor, which can be a bottleneck in traditional manufacturing processes. By minimizing manual intervention, companies can achieve faster turnaround times and respond more quickly to market demands.

Additionally, the ability to quickly switch between different designs and configurations enhances the flexibility of production schedules. This adaptability is particularly beneficial in industries that require rapid prototyping and iterative design processes.

Cost-Effectiveness

While the initial setup cost for CNC machining can be high, the long-term savings are considerable. The reduction in material waste, increased production speed, and decreased labor costs all contribute to making aluminum CNC machining a cost-effective solution.

By optimizing material usage and minimizing waste, CNC machining helps reduce the overall cost of production. This efficiency not only saves money but also supports sustainable manufacturing practices by minimizing resource consumption.

Moreover, the scalability of CNC machining allows businesses to adjust production volumes according to demand without incurring significant additional costs. This scalability ensures that companies can remain competitive and responsive to market changes without sacrificing profitability.

Versatility

CNC machines are incredibly versatile. They can be programmed to produce a wide range of complex shapes and designs, offering flexibility that traditional machining simply can’t match. This versatility allows for greater innovation and the ability to meet specific client requirements.

The adaptability of CNC machines extends beyond just shapes and designs. They can work with various materials and accommodate different finishes and textures, providing a comprehensive solution for diverse manufacturing needs. This flexibility enables companies to explore new product lines and expand their offerings without significant retooling or investment.

Additionally, the ability to quickly adapt to design changes and modifications is a significant advantage in industries where customization and personalization are valued. CNC machining allows businesses to tailor their products to meet unique customer specifications, enhancing customer satisfaction and loyalty.

Applications of Aluminum CNC Machining

Aluminum CNC services are used in various industries, each benefiting from the unique properties of aluminum and the precision of CNC machining. These applications demonstrate the versatility and impact of aluminum CNC machining across different sectors.

Automotive Industry

In the automotive sector, aluminum CNC machining is used to produce engine components, transmission parts, and other critical components. The lightweight nature of aluminum helps in improving fuel efficiency, while the precision of CNC machining ensures the reliability of these components.

The automotive industry is constantly evolving, with a growing emphasis on sustainability and performance. Aluminum’s light weight contributes to reduced vehicle emissions and improved fuel economy, aligning with industry trends towards greener transportation solutions.

Moreover, CNC machining enables the production of complex, high-performance parts that are essential for modern vehicles. Whether it’s for electric vehicles or traditional internal combustion engines, the precision and reliability of CNC-machined aluminum components are indispensable for achieving optimal performance and safety.

Aerospace Industry

The aerospace industry demands high precision and lightweight materials, making aluminum CNC machining an ideal choice. Components like aircraft frames, control panels, and landing gear parts are often made using this technology.

The aerospace sector is characterized by stringent safety and performance standards, necessitating the use of materials and manufacturing processes that can meet these requirements. Aluminum’s combination of strength and light weight makes it a preferred material for aerospace applications, where weight reduction is critical for fuel efficiency and payload capacity.

Furthermore, CNC machining provides the precision needed to manufacture components with tight tolerances, ensuring the reliability and safety of aircraft systems. This precision is crucial for maintaining the integrity of critical components in demanding operational environments.

Electronics Industry

In electronics, aluminum CNC machining is used to manufacture parts like heat sinks, enclosures, and other components that require high precision and thermal conductivity.

The electronics industry demands components that can efficiently dissipate heat and protect sensitive electronic circuits. Aluminum’s excellent thermal conductivity makes it an ideal material for heat sinks and enclosures, ensuring optimal performance and longevity of electronic devices.

CNC machining allows for the precise fabrication of intricate designs and complex geometries, enabling the production of parts that meet the specific requirements of electronic applications. This precision is essential for achieving high-performance electronics in increasingly compact and integrated designs.

Medical Industry

In the medical field, precision is paramount. Aluminum CNC machining is used to produce surgical instruments, prosthetics, and other critical components. The ability to produce intricate and precise parts makes CNC machining a preferred method in this industry.

The medical industry relies on components that can meet rigorous standards of precision and hygiene. CNC machining provides the accuracy needed to manufacture medical devices and instruments that meet these exacting standards, ensuring patient safety and effective treatment outcomes.

Additionally, aluminum’s biocompatibility and resistance to corrosion make it suitable for medical applications, where materials must withstand sterilization processes and prolonged exposure to bodily fluids. CNC machining enables the production of custom prosthetics and implants tailored to individual patient needs, enhancing the quality of care and improving patient outcomes.

Choosing the Right Aluminum CNC Service Provider

Selecting the right aluminum machining service is crucial for ensuring quality and efficiency. Here are some factors to consider, illustrated by industry leaders like JXD Machining, to guide your decision.

Experience and Expertise

Look for a service provider with a proven history of navigating aluminum’s unique challenges. For example, JXD Machining has honed over 15 years of expertise in aluminum CNC machining, successfully delivering complex components for aerospace clients requiring tight tolerances and automotive projects demanding lightweight durability. Their team’s familiarity with industry standards—such as ISO 9001 and AS9100—reflects a deep understanding of best practices, from optimizing CAD designs for aluminum’s thermal properties to resolving material-specific machining challenges.

A provider’s track record matters: JXD’s portfolio includes high-precision medical instruments and heat-resistant electronics enclosures, demonstrating how experience translates to consistent, high-performance results across sectors.

Technology and Equipment

Modern aluminum machining requires cutting-edge technology. Leading providers like JXD Machining invest in state-of-the-art CNC machines, such as 5-axis mills and high-speed routers, to achieve micron-level precision. Their adoption of advanced simulation software ensures designs are error-proofed in the digital realm before material is ever cut, minimizing waste and accelerating turnaround.

For instance, JXD’s integration of automated tool changers and real-time machining monitors allows them to handle both prototyping and large-scale production with equal efficiency, showcasing how technology drives flexibility and accuracy.

Customer Service

Effective collaboration hinges on transparent communication. JXD Machining exemplifies this by assigning dedicated project managers to oversee every stage, from initial design reviews to final quality inspections. Their commitment to clarity—such as providing detailed G-code breakdowns and material traceability reports—builds trust and ensures clients are never blindsided by delays or cost overruns.

Post-production support is equally vital: JXD’s team offers post-machining services like anodizing and surface finishing, paired with responsive troubleshooting, to ensure components meet end-use requirements seamlessly.

Cost and Turnaround Time

Balancing cost with value is key. While JXD Machining maintains competitive pricing, their true value lies in efficiency: their optimized workflows reduce material waste by up to 30% compared to traditional methods, while automated setups cut lead times for repeat projects. For clients in fast-paced industries like electronics, this means getting heat sinks or enclosures to market faster without compromising on thermal performance.

Long-term, their focus on durability—such as using aerospace-grade aluminum alloys—reduces lifecycle costs by minimizing component failure rates, making them a strategic partner for businesses prioritizing both quality and ROI.

Conclusion

Aluminum CNC services offer numerous benefits, from precision and efficiency to versatility and cost-effectiveness. Whether you’re in the automotive, aerospace, electronics, or medical industry, leveraging these services can significantly enhance your production capabilities and overall business performance. By choosing the right service provider, you ensure that you receive high-quality parts that meet your specific needs and help you stay competitive in your industry.

The strategic use of aluminum CNC machining can drive innovation and growth, enabling you to capitalize on new opportunities and stay ahead of the competition. As manufacturing continues to evolve, embracing advanced technologies and processes like CNC machining will be key to achieving long-term success and sustainability.