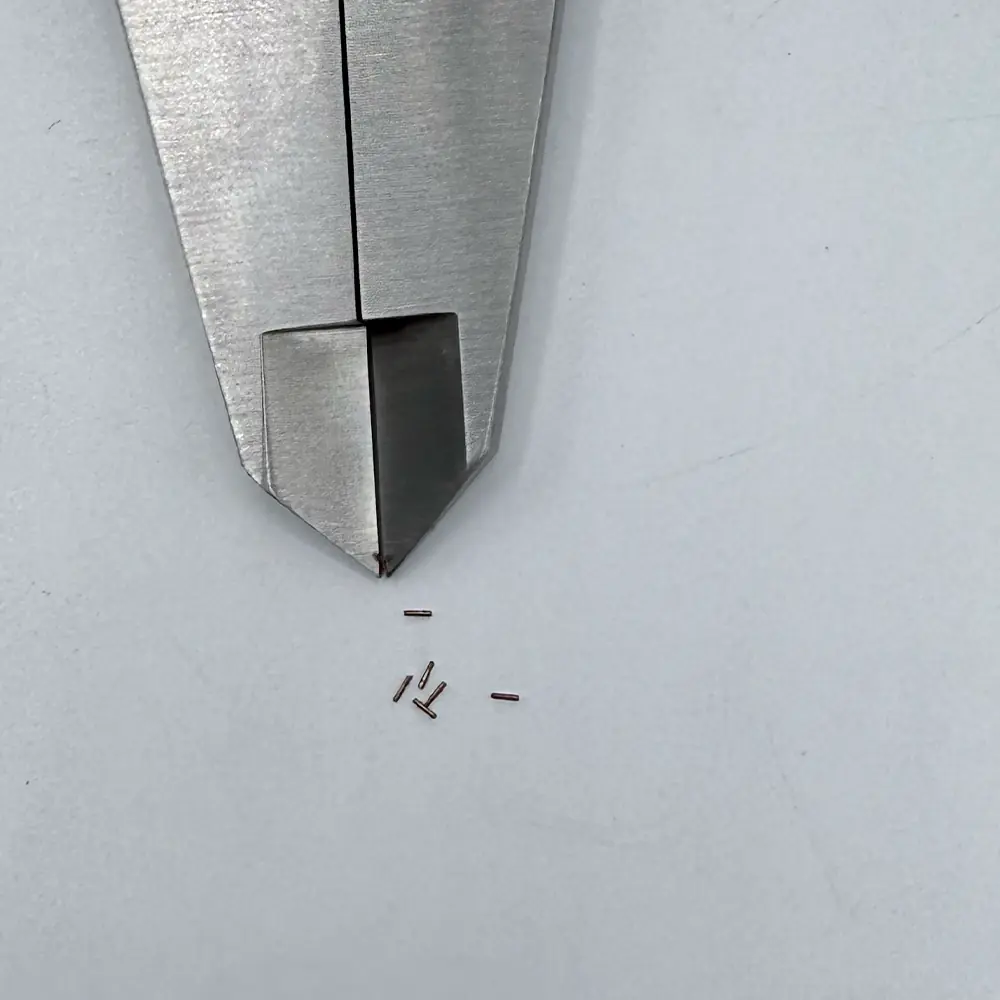

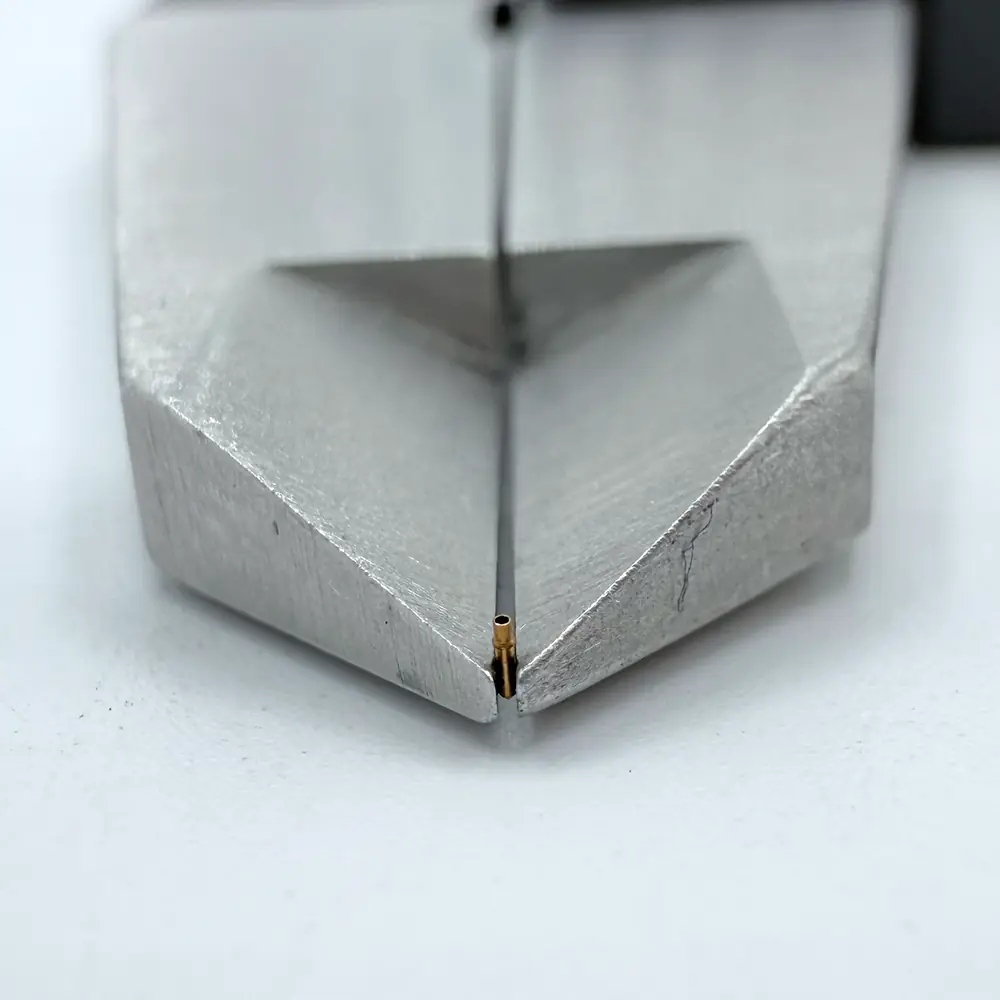

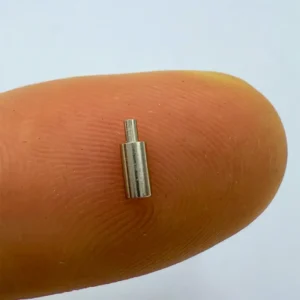

These Swiss-type lathe machined ESCO-compatible precision parts are specialized components produced via ESCO-series Swiss turning machines, designed for high-precision industrial assembly scenarios. As core accessories for ESCO equipment, they excel in scenarios requiring tight dimensional control—such as automotive transmission systems, medical device mechanisms, and aerosp2ace small-component assembly.

Crafted from high-grade stainless steel (304/316) or aluminum alloy (6061/7075), the parts offer customizable lengths from 5mm to 300mm, with a tolerance of up to ±0.005mm—ensuring seamless fit with ESCO machines’ operational standards. Surface treatments like passivation and electropolishing enhance corrosion resistance, making them suitable for harsh working environments (e.g., humid industrial workshops or chemical processing areas).

Key advantages include wear-resistant ESCO precision components performance (reducing replacement frequency) and low friction surfaces (lowering equipment operational noise). Whether for replacing worn ESCO parts or customizing new components for modified ESCO machines, these parts meet ISO 9001 quality standards—each unit undergoes CMM inspection to guarantee consistency. They are widely adopted by automotive, medical, and aerospace manufacturers seeking reliable ESCO-compatible machining solutions.

Our CNC Machining Facilities & Capabilities

Want to see our workshop layout, equipment, and production process? Click here for our “About Us” page.

Quality Assurance

Incoming Check: Verify raw material certificates + sample tests (hardness, composition) to rule out defects.

In-Process Inspection: Spot-check critical stages with CMMs to validate tolerances (±0.001mm) early.

100% Final Test: Full dimensional, surface roughness, and functional checks—only passers move forward.

Outbound Review: Secure packaging + batch labeling; test reports/certifications included for traceability.