Choosing a qualified CNC machining partner is never about who has the flashiest website or the lowest quote. In the world of high-precision manufacturing, the moment the spindle starts rotating, any minor design flaw or management oversight becomes an expensive scrap order.

For engineers and procurement professionals in the aerospace, medical, and semiconductor industries, evaluating a CNC machine shop requires looking past marketing rhetoric to verify three core pillars: Quality Control Logic, Metrological Infrastructure, and Material Integrity.

Equipment Infrastructure: Technical Maturity Beyond Axis Count

When a supplier claims “5-axis capability,” consider it merely the entry ticket. What truly separates a top-tier shop is its machine’s geometric accuracy, thermal stability, and maintenance discipline.

The Dimensional Advantage of Simultaneous 5-Axis Machining

Standard 3-axis VMCs require multiple setups and directional clamping for complex parts. Every manual repositioning introduces stacking errors.

-

The Pro Difference: A shop with Simultaneous 5-axis capabilities can complete complex geometries in a single setup. This isn’t just about speed; it’s about ensuring near-perfect relative positional accuracy between intricate features.

| Machine Type | Axis Configuration | Typical Applications | Precision Risk Points |

| 3-Axis VMC | X, Y, Z | Simple bases, covers | Datum shifts from multiple clamping |

| 4-Axis Horizontal | X, Y, Z + Rotary | Valve bodies, manifolds | Indexing accuracy & pallet exchange errors |

| 5-Axis Simultaneous | X, Y, Z + A, B/C | Impellers, medical implants | Rotational axis compensation & post-processor bugs |

Thermal Stability: The 21°C (70°F) Benchmark

High-performance machines like DMG MORI or Mazak are designed for high-intensity cutting. However, if they sit in a non-climate-controlled workshop, the thermal expansion of the cast iron body can ruin precision fits.

Note: A part measured at a standard 21°C (70°F) will already be out of tolerance if produced in a shop reaching 38°C (100°F) without environmental compensation.

Preventive Maintenance: Rejecting “Run to Failure”

Always ask for Ball-bar test records. This test reflects the machine’s circularity error, backlash, and perpendicularity. If a shop only repairs machines when they break down, their process is uncontrollable. Look for daily monitoring of coolant concentration and regular spindle vibration analysis—these are the hallmarks of a shop that controls the process rather than gambling on luck.

Quality Management: Deep Audits of Compliance

ISO 9001 certificates are ubiquitous but often purely decorative. For high-reliability projects, you must examine how the quality system is integrated into daily operations.

Industry-Specific Compliance Thresholds

| Standard | Core Focus | Critical Documents to Audit |

| ISO 9001 | General Quality Management | Quality manual, MRB (Material Review Board) logs |

| AS9100 | Aerospace & Defense | Key Characteristic (KC) plans, AS9102 reports |

| IATF 16949 | Automotive Industry | PPAP, FMEA, and SPC charts |

| ISO 13485 | Medical Devices | Process validation (IQ/OQ/PQ records) |

The Hardcore Requirements of First Article Inspection (FAI)

An FAI is not just measuring a few parts; it is a validation of the entire process chain. A professional First Article Inspection Report (FAIR) should be a “digital clone” of the drawing:

-

Ballooned Drawing: Every tolerance and technical requirement numbered for zero-omission tracking.

-

Actual Measurement Data: Listing nominal values vs. actual results. If data is marginal, an elite supplier proactively analyzes the root cause rather than just marking it “pass.”

-

Traceability Certification: Original Material Test Reports (MTR) and certifications for outsourcing (heat treatment, plating) must be attached.

Metrology: Precise Measurement is the Premise of Manufacturing

A workshop’s precision is strictly limited by its measuring tools. If a shop attempts to measure $\pm 0.0005″$ tolerances with manual calipers, they lack the basic understanding of metrology.

The Necessity of CMM (Coordinate Measuring Machine)

For complex GD&T (positional tolerance, profile, or concentricity), manual tools are powerless. However, owning a CMM is only the first step. The programming logic is what matters—an incompetent programmer can make a failing part look “perfect” by reducing data points or using incorrect datum alignment.

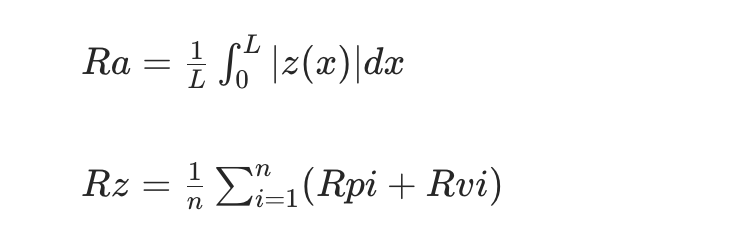

Surface Finish: The Ra vs. Rz Misunderstanding

Surface finish isn’t just about “looking shiny.” In seal applications, Ra (Arithmetic Mean) is a deceptive indicator because it averages out deep scratches. Rz (Ten-Point Height) focuses on the maximum peaks and valleys.

Case Study: For a hydraulic piston rod, a qualified Ra might still fail if the Rz is too high. The sharp microscopic “peaks” will wear down seals like sawteeth, leading to system leakage. A professional supplier will recommend the correct parameter based on the part’s function.

Material Traceability: Eliminating “Gray Market” Risks

Material substitution (e.g., using 6061 aluminum instead of Aerospace-grade 7075-T6) is a significant threat to part longevity.

-

MTR Verification: The Heat Number on the physical material must perfectly match the original mill’s Material Test Report.

-

Positive Material Identification (PMI): Leading shops use handheld XRF analyzers. In seconds, the device determines the exact chemical composition (Nickel, Molybdenum, etc.). Our philosophy at JXD Machining: “Trust the paperwork, but verify the atoms.”

The DFM Mindset: Design for Manufacturability

An elite CNC machine shop acts as your consultant. A cold quote means nothing; a detailed DFM report can save you thousands.

-

Internal Corner Radii: Rotary tools cannot cut sharp 90° internal corners. If allowed to be slightly larger than the tool radius, machining speed increases by 300%.

-

Deep Hole Ratios: Holes exceeding a 10:1 length-to-diameter ratio risk deflection. We suggest processing from both ends or adjusting tolerances to ensure success.

-

Tolerance Rationality: Applying $\pm 0.0001″$ to non-mating features only drives up scrap rates and costs without adding functional value.

Digital Ecosystem: Seamless Integration from CAD to ERP

Modern CNC manufacturing is no longer an island. An excellent supplier achieves digital integration where CAD models are directly imported into CAM software to generate toolpaths, and ERP systems track part locations in real-time.

If a shop still relies on manual data entry for every step, they are prone to version control errors—the industry-classic disaster of machining V2.0 parts using V1.0 drawings.

Workshop Culture: The Human Element

Despite automation, precision is a human discipline. The “technical heritage” of a shop is ultimately reflected in the discipline of its workers.

-

“Button Pushers” vs. “Genuine Machinists”: In low-end shops, operators often don’t understand metal cutting. When vibration or “chatter” occurs, they are helpless.

-

The Machinist Advantage: Genuine machinists hear subtle sound changes before a tool breaks, know how to compensate for residual material stress, and perform dynamic balance checks on every tool.

Observations for your next tour: Is the tool cart organized? Are the gages labeled with green calibration stickers? Their attitude toward thin-walled deformation tells you if they are a partner or just a vendor.

Conclusions and Actionable Steps

Choosing a CNC shop is essentially choosing a technical risk management partner. A qualified supplier must balance infrastructure, quality systems, metrology, and talent.

Your Audit Checklist Summary:

-

Hardware: Temperature-controlled environment? Ball-bar records?

-

System: Rigorous FAI process? Industry-specific certifications?

-

Measurement: CMM capability? Ra vs. Rz expertise?

-

Materials: Closed-loop MTR traceability? PMI verification?

-

Consultancy: In-depth DFM analysis provided during the quote?

At JXD Machining, we don’t just produce parts; we eliminate uncertainty in your supply chain. Our reverence for “thousandth-of-an-inch” precision ensures your design intent is realized perfectly.

Ready to see how your design performs in production?

[Upload your CAD drawings (STEP/IGS)]and our application engineers will generate a free DFM report within 24 hours.