JXD Machining – Your Trusted CNC Machining Partner

In the realm of modern precision manufacturing, material testing stands as a cornerstone for ensuring product performance, safety, and compliance. As a leading provider of CNC machining solutions, JXD Machining understands that rigorous material testing is not just a quality control step—it’s a strategic investment in product reliability, innovation, and operational excellence. By systematically evaluating how materials behave under various conditions, we empower our clients to make data-driven decisions that elevate their manufacturing processes and final products.

The Strategic Importance of Material Testing in CNC Machining

For industries relying on precision components—from aerospace to medical devices—material testing delivers three critical advantages:

1. Engineering Excellence Through Data

By measuring mechanical properties like tensile strength, hardness, and fatigue resistance, JXD Machining’s testing protocols provide actionable insights for optimizing CNC machining parameters. For example:

Analyzing the yield strength of titanium alloys helps us refine cutting speeds for aerospace components, reducing tool wear while maintaining dimensional accuracy.

Studying the thermal conductivity of aluminum alloys guides our cooling strategies in high-speed machining, preventing heat-induced deformations in complex structures.

2. Material-Specific Process Optimization

CNC machining demands precision across diverse materials—metals, plastics, and composites each have unique behavior during milling, turning, or drilling. Our testing ensures:

Machinability Assessment: Evaluating chip formation and surface roughness potential in materials like stainless steel 316L to optimize tool geometry and lubrication strategies.

Formability Verification: Using bend tests and sheet metal stretch forming analysis to ensure materials can withstand the stresses of CNC forming without cracking or springback.

3. End-to-End Quality Assurance

From raw material intake to finished part inspection, JXD Machining integrates testing into every phase:

Incoming Material Testing: Spectrometric analysis to confirm alloy composition compliance (e.g., verifying 6061-T6 aluminum tempering for structural components).

Process Validation: Non-destructive testing (NDT) like ultrasonic scanning to detect internal defects in machined parts, ensuring compliance with AS9100 aerospace standards.

Comprehensive Material Testing Solutions for Precision Manufacturing

A. Mechanical Property Testing: Foundations of Component Reliability

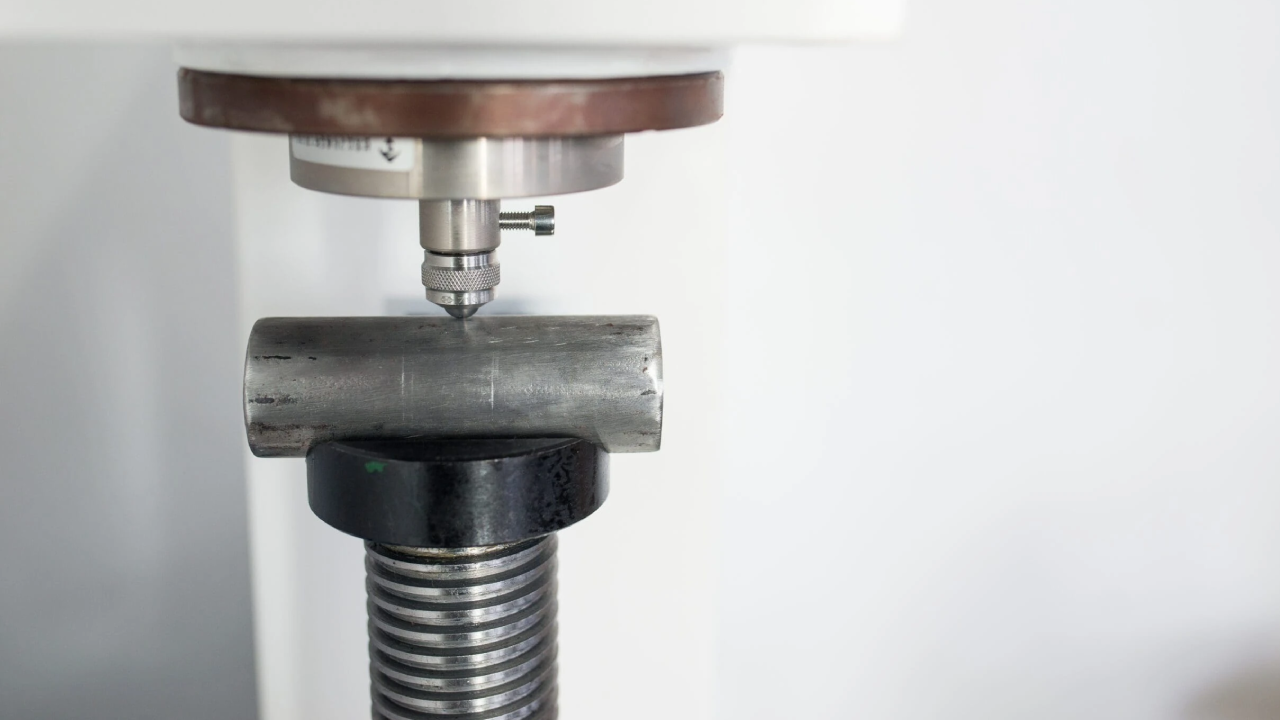

1. Tensile & Compressive Testing

Using INSTRON universal testing machines, we measure:

Ultimate Tensile Strength (UTS) in aerospace-grade titanium (Ti-6Al-4V) to ensure load-bearing components meet design specifications.

Compressive Yield Strength in engineering plastics (e.g., PEEK) for medical device components, critical for resisting deformation under cyclic loading.

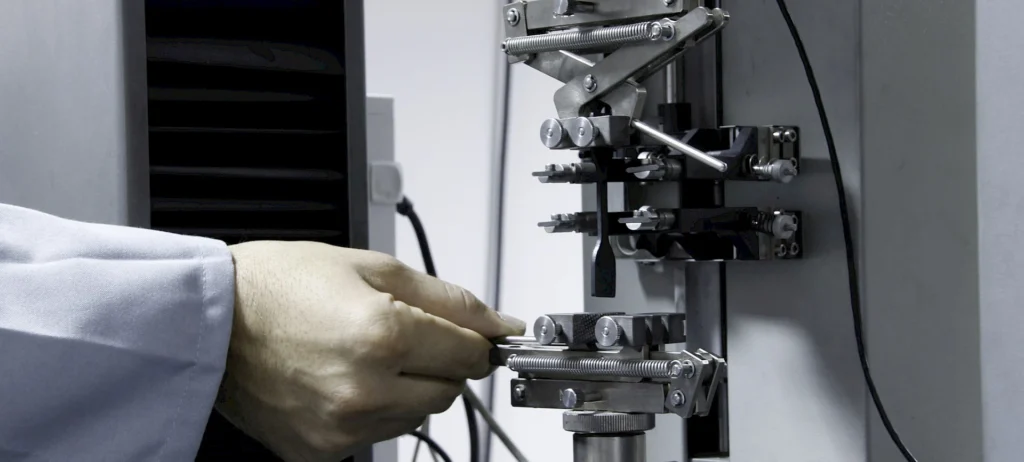

2. Fatigue & Fracture Testing

Our servo-hydraulic fatigue testing systems simulate real-world stresses:

Predicting the service life of automotive transmission gears subjected to millions of load cycles.

Identifying stress concentration points in CNC-machined aerospace brackets through fracture surface analysis (using ZEISS SEM).

B. Environmental & Functional Performance Testing

1. Thermal & Corrosion Resistance

Thermal Cycling Tests (-50°C to 150°C) for electronic enclosure materials, ensuring dimensional stability in extreme operating environments.

Salt Spray Testing (ASTM B117) for marine-grade stainless steel components, verifying corrosion resistance beyond 1,000 hours of exposure.

2. Non-Destructive Testing (NDT) Excellence

Our ASNT-certified technicians use:

Magnetic Particle Inspection to detect surface flaws in ferromagnetic materials (e.g., carbon steel shafts).

X-Ray Radiography for casting defect analysis in complex aluminum components, ensuring structural integrity without material loss.

C. Machining-Specific Tests for Process Optimization

1. Chip Breakability Evaluation

Critical for automated CNC machining, we assess how materials like carbon steel form chips during cutting, optimizing feed rates to prevent tool clogging and improve surface finish (Ra ≤ 0.8μm).

2. Surface Integrity Analysis

Using microhardness testers and optical profilometers, we evaluate:

Subsurface hardness changes induced by machining forces in hardened steels (e.g., H13 tool steel).

Surface roughness compliance with aerospace standards (NAS 1638 Class 1) for optical components.

Industry Applications: Where Precision Meets Performance

1. Aerospace & Defense

Turbine Blade Manufacturing: Grain orientation analysis in nickel-based superalloys (Inconel 718) to enhance fatigue resistance in high-temperature environments.

Landing Gear Components: Ultrasonic thickness testing to ensure wall thickness consistency in CNC-machined titanium forgings.

2. Medical Device Manufacturing

Orthopedic Implants: Biocompatibility testing (ISO 10993) for cobalt-chromium alloys, combined with microstructural analysis to ensure corrosion resistance in body fluids.

Surgical Instruments: Torsion testing of stainless steel 420 to validate torque transmission efficiency in precision tools.

3. Industrial Equipment & Electronics

High-Precision Gears: Pitch deviation testing and surface hardness mapping to ensure noise-free operation in robotic components.

Heat Sinks: Thermal impedance testing in copper-aluminum composites, optimizing CNC-machined fin structures for maximum heat dissipation.

Overcoming Testing Challenges in Precision Manufacturing

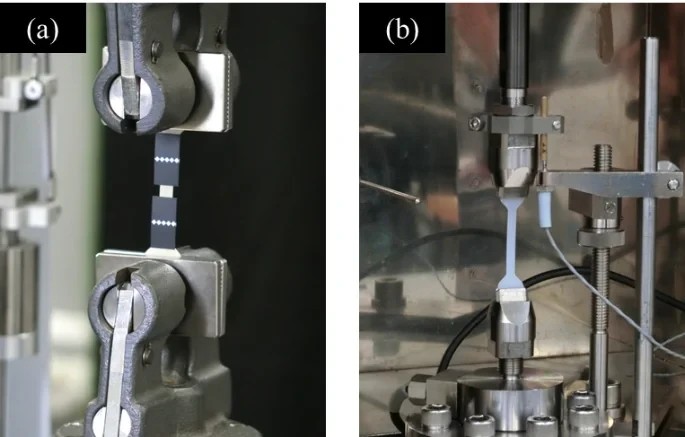

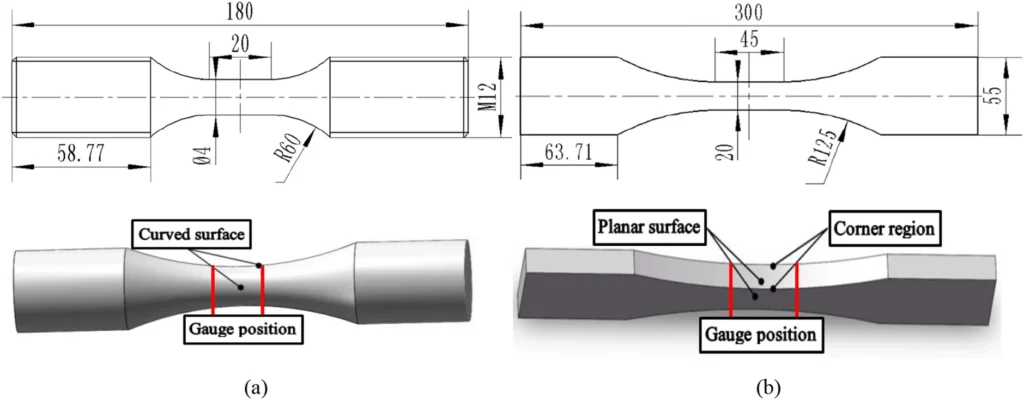

1. Sample Preparation Consistency

JXD Machining addresses variability through:

Standardized CNC machining of test specimens (ISO 6892-1 compliant) using precision lathes and grinders.

3D coordinate measuring machines (CMM) to verify dimensional accuracy within ±0.001mm tolerance.

2. Multifactorial Environmental Simulation

Our controlled labs replicate real-world conditions:

Humidity-controlled chambers (20-95% RH) for testing polymer degradation in outdoor equipment.

High-speed tensile testing systems (10m/s) to evaluate dynamic material behavior in impact-resistant components.

3. Efficiency & Cost-Effectiveness

For low-volume, high-mix production:

Modular testing protocols that combine tensile, hardness, and NDT in a single workflow, reducing lead times by 30%.

Predictive analytics using historical data to recommend cost-effective material substitutions (e.g., aluminum 7075 for titanium in non-critical components).

JXD Machining Testing Competency: Precision Redefined

As a vertically integrated CNC machining provider, our in-house testing laboratory is equipped to handle the most demanding material challenges:

1. Advanced Equipment Fleet

Mechanical Testing: INSTRON 5982 (500kN capacity), Zwick Roell hardness testers (Rockwell, Vickers, Brinell).

Metallurgical Analysis: Olympus optical microscopes, Bruker spectroscopes for elemental composition verification.

NDT Solutions: GE Inspection Technologies ultrasonic flaw detectors, Yxlon X-ray systems for sub-surface imaging.

2. Certified Compliance

Standards Adherence: ASTM, ISO, AMS, and customer-specific requirements (e.g., IPC-6012 for electronic components).

CNAS Accreditation: Ensuring test data acceptability in global supply chains, from Tier 1 automotive to medical device manufacturers.

3. Partner-Centric Services

Custom Test Plans: Collaborative design of testing regimes for novel materials (e.g., carbon fiber-reinforced polymers for UAV components).

Failure Analysis Reports: Detailed root-cause analysis with recommendations for process adjustments, minimizing client downtime.

Conclusion: Testing as a Competitive Advantage

In an era where precision tolerances (±0.0005mm) and material innovation define manufacturing leadership, material testing is no longer a quality checkpoint—it’s a strategic differentiator. JXD Machining leverages decades of CNC machining expertise, state-of-the-art equipment, and rigorous testing protocols to ensure every component we produce meets the highest standards of performance and reliability.

Whether you’re developing a next-generation aerospace component, a life-saving medical implant, or a high-precision industrial part, our testing solutions provide the confidence that your materials will perform—exactly as designed, under any condition.

Partner with JXD Machining to transform material data into manufacturing excellence. Let’s engineer precision together.