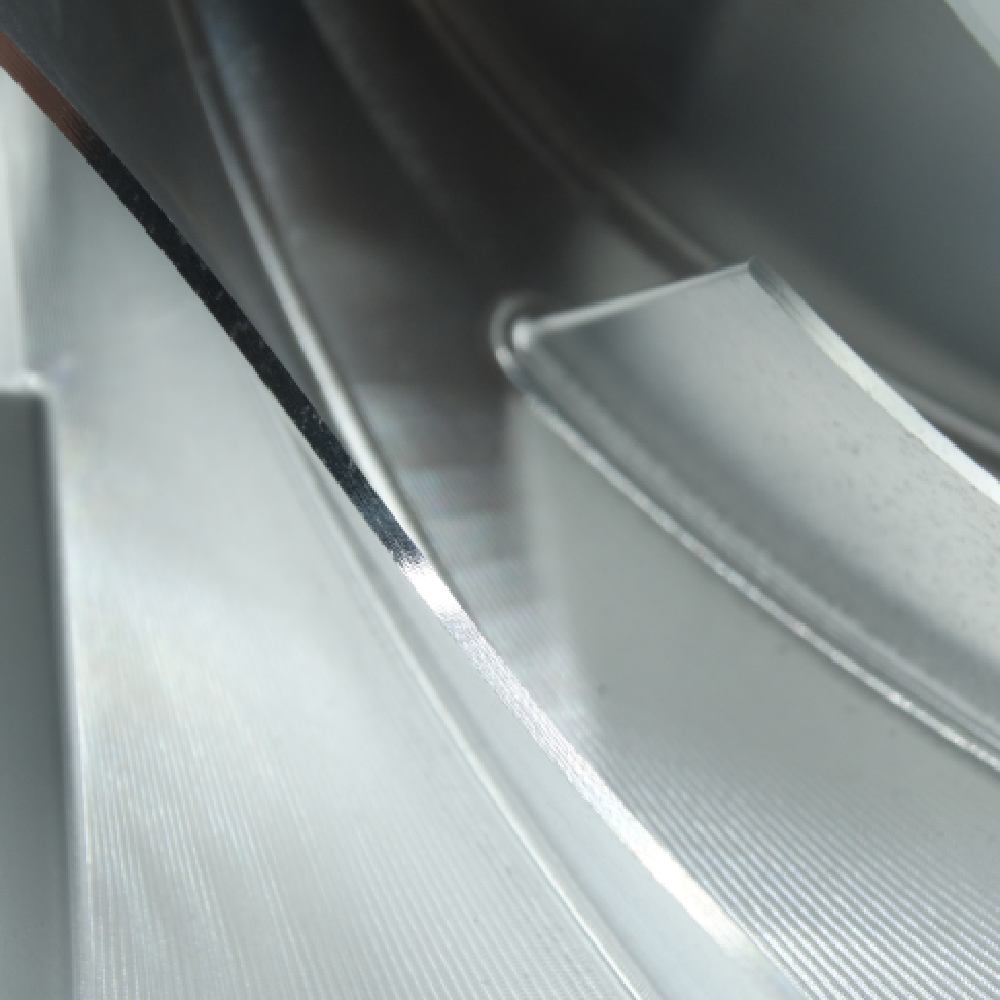

Our precision CNC machined aluminum turbo impeller is engineered for high-performance industrial and turbocharger applications, delivering exceptional dimensional accuracy and dynamic balance. Fabricated from high-strength aluminum alloy (7075/6061), this custom turbine component undergoes advanced 5-axis CNC milling and precision turning processes to achieve tight tolerances of ±0.02mm and a flawless blade surface finish.

Ideal for turbo systems, industrial turbines, and fluid dynamics equipment, this custom aluminum turbo impeller ensures optimal airflow, corrosion resistance, and seamless integration into your high-performance systems. Whether you need a standard design or a fully customized impeller for unique turbo applications, our machining capabilities guarantee precision in every blade and contour.

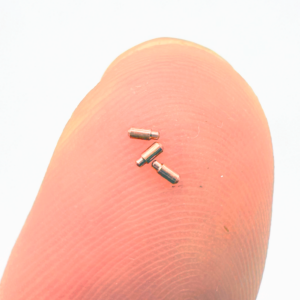

We offer a low MOQ of 10 pieces, fast sample lead times of 7-10 days, and bulk production delivery within 15-20 days. With OEM/ODM services, we can tailor dimensions, blade geometry, and surface treatments to your exact specifications. Choose our CNC machined aluminum turbo impeller for reliability, efficiency, and peak performance in demanding industrial environments.

Our CNC Machining Facilities & Capabilities

Want to see our workshop layout, equipment, and production process? Click here for our “About Us” page.

Quality Assurance

Incoming Check: Verify raw material certificates + sample tests (hardness, composition) to rule out defects.

In-Process Inspection: Spot-check critical stages with CMMs to validate tolerances (±0.001mm) early.

100% Final Test: Full dimensional, surface roughness, and functional checks—only passers move forward.

Outbound Review: Secure packaging + batch labeling; test reports/certifications included for traceability.