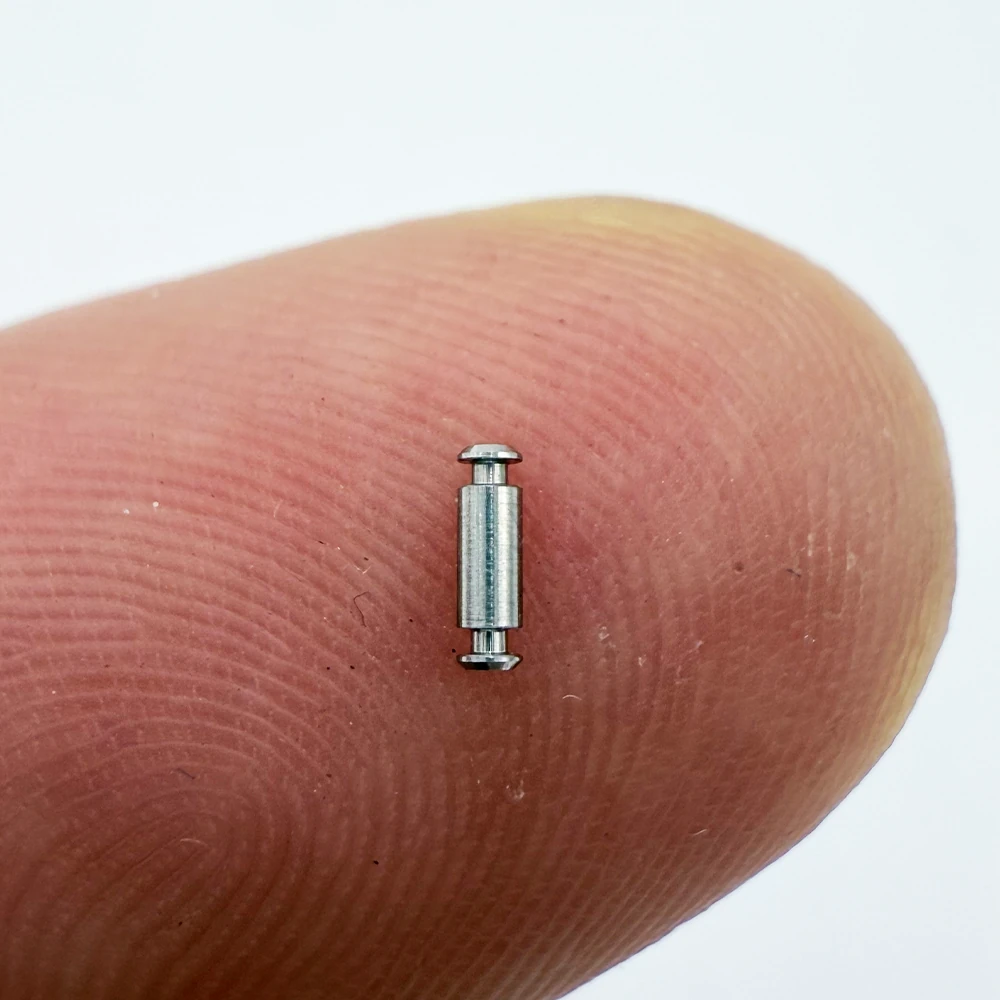

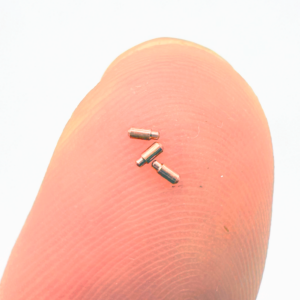

This CNC machined stainless steel micro pin with double head is designed for applications where miniature precision and durability are critical. Manufactured through Swiss-type CNC turning technology, each pin is produced under strict tolerances (±0.01mm) to guarantee dimensional accuracy and stable performance.

Made from high-quality stainless steel, the micro pin provides excellent corrosion resistance, wear resistance, and long-term reliability, making it suitable for demanding environments. Surface treatment options such as polishing, passivation, or plating can be customized to enhance performance and appearance.

Typical applications include medical devices, aerospace instruments, miniature electronic connectors, testing equipment, and precision mechanical assemblies. With flexible prototyping, small batch production, and large-scale manufacturing capability, we ensure that every order meets international standards.

Whether you need custom stainless steel micro pins or a full OEM solution, our advanced machining expertise and strict quality control make us your reliable manufacturing partner.

Our CNC Machining Facilities & Capabilities

Want to see our workshop layout, equipment, and production process? Click here for our “About Us” page.

Quality Assurance

Incoming Check: Verify raw material certificates + sample tests (hardness, composition) to rule out defects.

In-Process Inspection: Spot-check critical stages with CMMs to validate tolerances (±0.001mm) early.

100% Final Test: Full dimensional, surface roughness, and functional checks—only passers move forward.

Outbound Review: Secure packaging + batch labeling; test reports/certifications included for traceability.