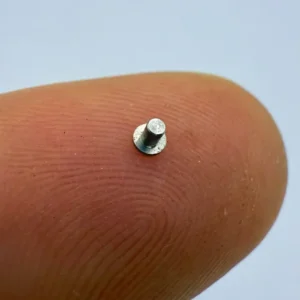

Constructed from C3604 brass with 3–5μm gold plating, these pins feature Swiss-type CNC turning for ±0.01mm dimensional accuracy.

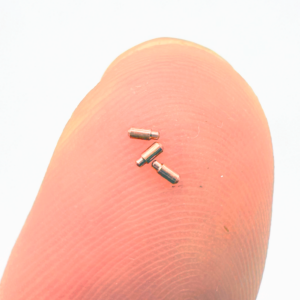

These gold plated brass precision pins are essential components in electronics testing systems, manufactured via Swiss-type CNC turning to achieve ultra-precise dimensional control (±0.01mm tolerance). Constructed from C3604 brass—renowned for its superior machinability and electrical conductivity—each pin undergoes gold plating (3–5μm thickness) to enhance corrosion resistance and ensure stable electrical performance in test sockets, probes, and connectors.

Ideal for industries including consumer electronics, automotive electronics, and semiconductor testing, these pins support customizable lengths (5mm–50mm) and diameters (0.5mm–5mm) to match unique test fixture requirements. The gold plating not only boosts conductivity but also extends service life by resisting wear during repeated insertions. With sample lead times of 3–5 days and bulk production in 7–12 days, they enable rapid prototyping and mass production for testing solution providers.

Every pin undergoes rigorous quality checks: dimensional verification via micrometers and plating thickness analysis via XRF to meet RoHS and industry standards. Customization options include alloy selection (e.g., 304 stainless steel), plating variations (nickel, silver), and specialized tip geometries for niche testing scenarios.

Our CNC Machining Facilities & Capabilities

Want to see our workshop layout, equipment, and production process? Click here for our “About Us” page.

Quality Assurance

Incoming Check: Verify raw material certificates + sample tests (hardness, composition) to rule out defects.

In-Process Inspection: Spot-check critical stages with CMMs to validate tolerances (±0.001mm) early.

100% Final Test: Full dimensional, surface roughness, and functional checks—only passers move forward.

Outbound Review: Secure packaging + batch labeling; test reports/certifications included for traceability.