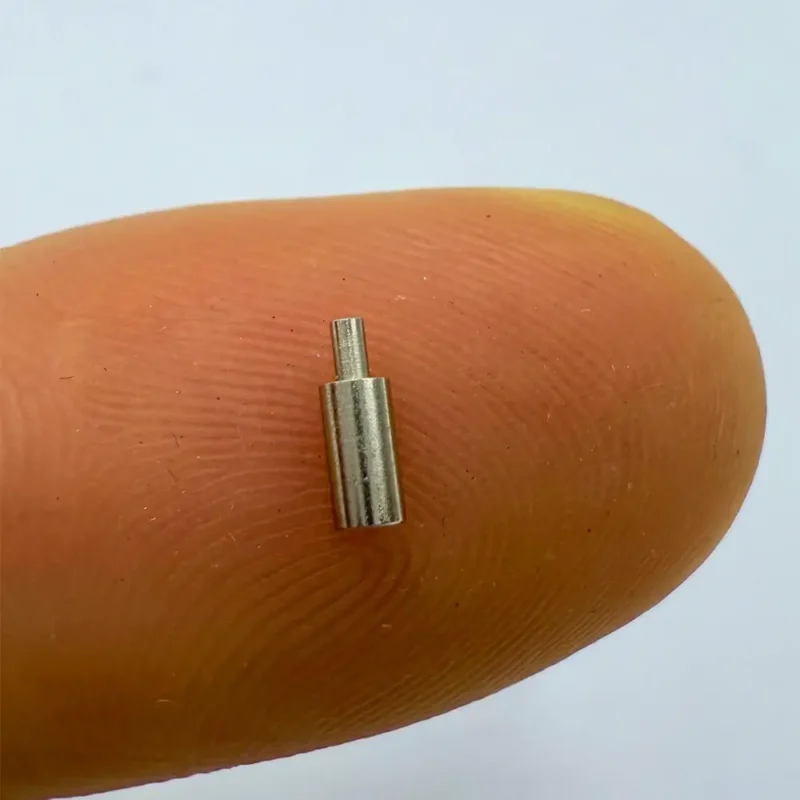

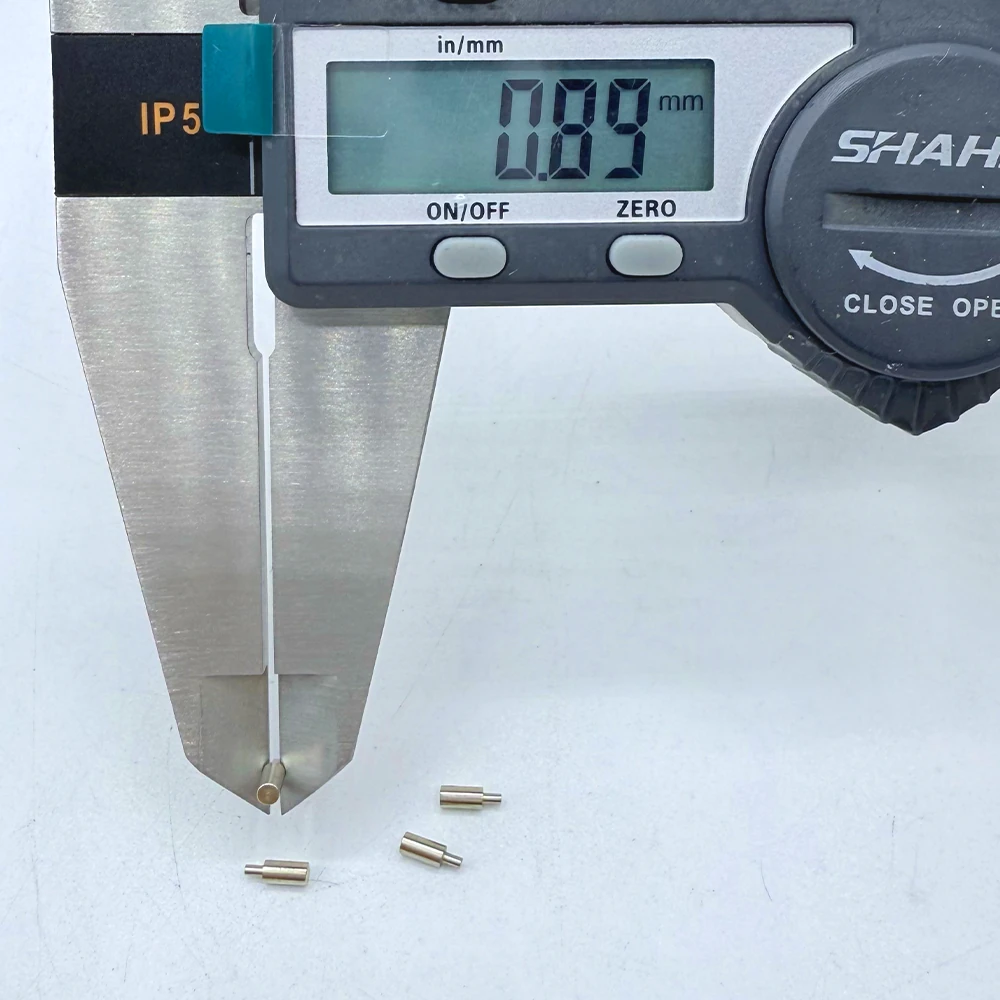

Precision steel step pins are essential miniature components meticulously engineered for high-precision mechanical and electronic assemblies where dimensional accuracy and structural reliability are critical. Defined by their stepped cylindrical design, these pins enable seamless integration into tight-tolerance applications—with key dimensions (such as the smaller shaft diameter, verified at approximately 0.89mm via digital calipers) ensuring flawless fit and function.

Crafted from high-grade precision steel, these pins offer exceptional corrosion resistance, wear resistance, and dimensional stability—making them ideal for industries including medical device manufacturing (e.g., surgical instruments, diagnostic equipment), micro-electronics (such as sensor modules, connectors, and miniaturized circuitry), precision instrumentation, and advanced watchmaking. Fabricated through CNC turning and precision machining processes, each pin adheres to ultra-tight tolerances (typically within ±0.01mm) to guarantee consistency across production runs.

The polished surface finish not only enhances aesthetic uniformity but also reduces friction during installation and operational use—improving assembly efficiency and extending the service life of integrated systems. Whether utilized in standard configurations or customized for project-specific requirements, these high-precision steel step pins deliver the precision and durability needed to power critical miniature technologies.

Our CNC Machining Facilities & Capabilities

Want to see our workshop layout, equipment, and production process? Click here for our “About Us” page.

Quality Assurance

Incoming Check: Verify raw material certificates + sample tests (hardness, composition) to rule out defects.

In-Process Inspection: Spot-check critical stages with CMMs to validate tolerances (±0.001mm) early.

100% Final Test: Full dimensional, surface roughness, and functional checks—only passers move forward.

Outbound Review: Secure packaging + batch labeling; test reports/certifications included for traceability.