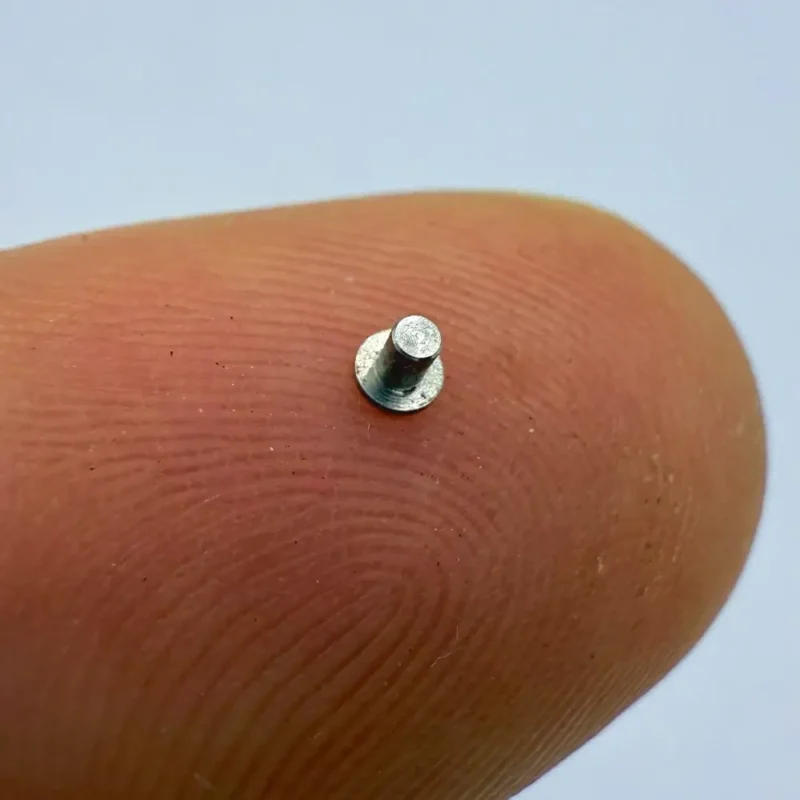

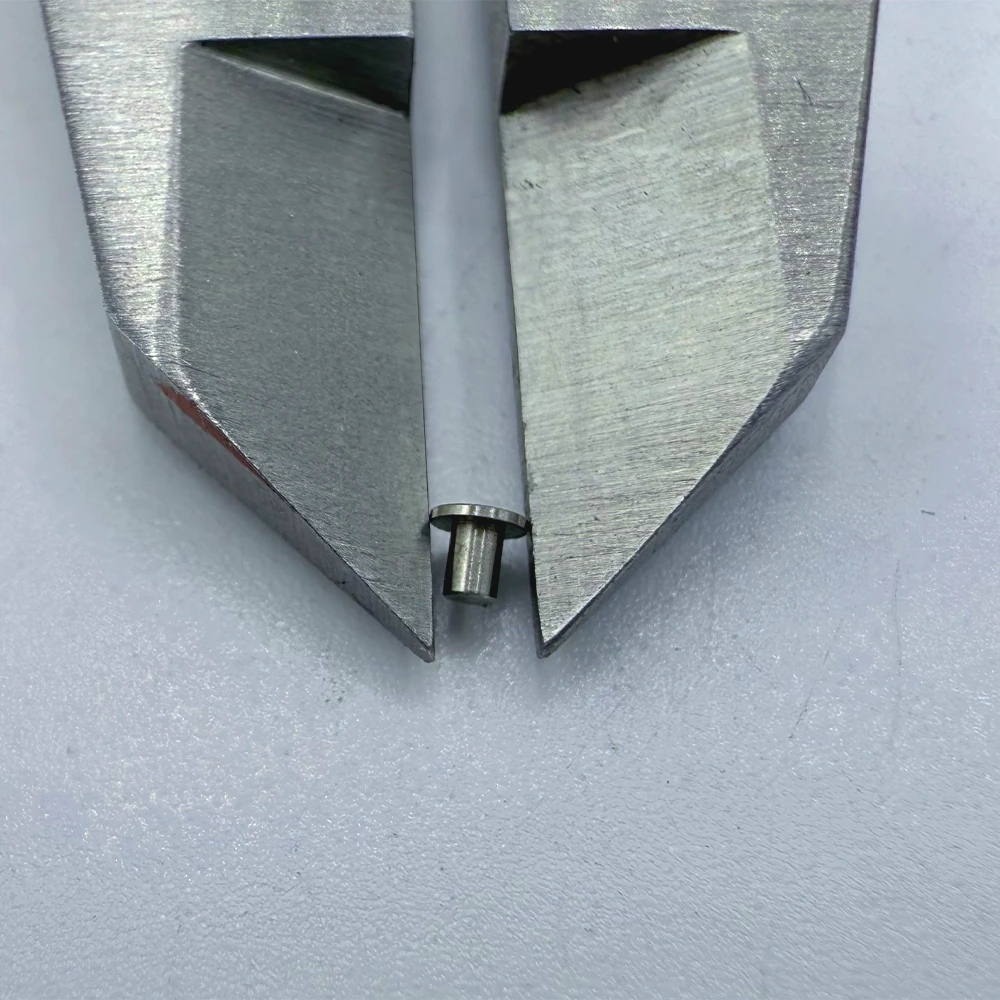

These stainless steel precision micro rivets are critical components in electronics assembly, manufactured via Swiss-type CNC turning to achieve ultra-precise dimensional control (±0.01mm tolerance). Constructed from 304 stainless steel, they deliver exceptional corrosion resistance—making them suitable for environments with moisture or temperature fluctuations (such as consumer electronics, automotive electronics, and medical device enclosures).

The polished surface finish ensures smooth insertion into delicate circuit boards and housings, while the material’s inherent strength provides reliable shear resistance for long-term assembly stability. With customizable diameters (0.5mm–5mm) and lengths (1mm–10mm), these rivets can be tailored to match unique design requirements for connectors, shields, and structural supports.

Sample lead times of 3–5 days and bulk production in 7–12 days enable rapid prototyping and efficient mass production. Every rivet undergoes rigorous quality checks: dimensional verification via micrometers and surface finish inspection to ensure consistency. Customization options include alloy variations (e.g., 316 stainless steel), plating treatments (nickel for enhanced conductivity), and geometry adjustments for niche applications.

Our CNC Machining Facilities & Capabilities

Want to see our workshop layout, equipment, and production process? Click here for our “About Us” page.

Quality Assurance

Incoming Check: Verify raw material certificates + sample tests (hardness, composition) to rule out defects.

In-Process Inspection: Spot-check critical stages with CMMs to validate tolerances (±0.001mm) early.

100% Final Test: Full dimensional, surface roughness, and functional checks—only passers move forward.

Outbound Review: Secure packaging + batch labeling; test reports/certifications included for traceability.