Concept Definition: Technological Leap from Prototyping to Rapid Manufacturing

Rapid Prototyping (RP) originated in the 1980s, with its core principle being the construction of three-dimensional solid objects based on the “layered superimposition” method. Its most distinctive feature is breaking free from the reliance on molds in traditional manufacturing, with the entire process driven by digital models. As an advanced direction of RP, Rapid Manufacturing (RM) differs in that it directly targets the production of end-use functional parts—such as small-batch customized interior components in the automotive industry and personalized implants in the medical field—rather than being limited to prototype verification. While their technical pathways are highly overlapping, there are fundamental differences in their application objectives. However, from the perspective of current industrial practice, RM still requires continuous optimization in terms of production efficiency (e.g., single-part manufacturing time), material performance (e.g., long-term aging resistance), and cost control (e.g., equipment depreciation allocation) in combination with specific industry scenarios.

Core Technology System: Characteristics and Evolution of Mainstream Processes

Currently, the three most mature RP technologies in industrial applications all follow the logic of “layered discretization + superimposed forming,” but they differ significantly in material compatibility and precision performance. Selection in practical applications should be based on specific scenarios:

- Stereolithography Apparatus (SLA): Uses liquid photosensitive resin as raw material, which is cured point-by-point by ultraviolet laser. In practical applications, the industrial-grade ProX 800 equipment from 3D Systems can stably control precision within ±0.13mm (±0.005″) and achieve a surface roughness of Ra 2.0-3.5μm when manufacturing home appliance shell prototypes, making it suitable for scenarios requiring high appearance precision.

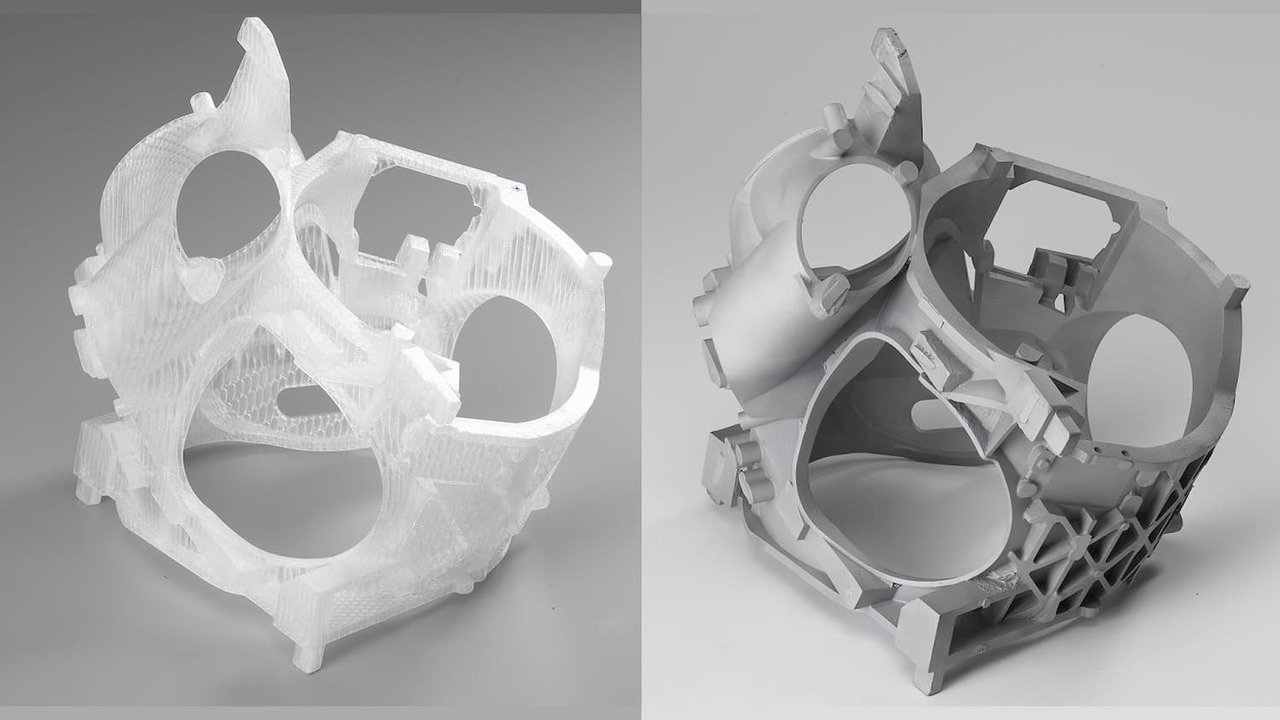

- Selective Laser Sintering (SLS): Proposed by Professor C. R. Dechard from the University of Texas (USA) in 1989, it was initially used for nylon powder forming. The key advantage of this process is that unsintered powder can naturally support complex structures—for example, in the trial production of aerospace components, the EOS M 290 equipment can sinter Ti-6Al-4V powder to directly manufacture fuel nozzles with internal flow channels, without the need for additional support design, resulting in almost unlimited geometric freedom.

- Fused Deposition Modeling (FDM): Forms parts by extruding filaments (e.g., ABS, PLA) through a heated nozzle, with relatively low equipment costs. Taking the commonly used prototype-grade Ultimaker S5 equipment as an example, when printing a 300mm×200mm×100mm plastic structural part, the tolerance is usually ±0.5% (with a lower limit of ±0.5mm), making it more suitable for manufacturing structural verification prototypes. Post-polishing is required for scenarios with high precision requirements.

In recent years, hybrid processes have gradually overcome the limitation of single-material use in traditional RP technologies. For instance, the FX10 printer from Markforged integrates Fused Filament Fabrication (FFF) and Metal FFF processes—it first prints a carbon fiber-reinforced plastic matrix via FFF, then embeds metal filaments, and finally processes the part through a three-step “printing-debinding-sintering” method. This enables the manufacturing of aerospace connectors (e.g., UAV landing gear brackets) that combine strength and lightweight properties. In applications at an aerospace supporting enterprise in Shenzhen, this type of equipment has realized the integrated manufacturing of small-batch (fewer than 50 pieces) components, reducing working hours by 40% compared to the traditional combined process of “plastic printing + metal processing.”

Core Technical Advantages: Reconstructing the Underlying Logic of Manufacturing

The most prominent value of RP technology lies in breaking the geometric limitations of traditional subtractive manufacturing (e.g., milling, grinding). For example, when manufacturing fuel nozzles for aero-engines using the SLS process, it is possible to directly form long, narrow thin-walled flow channels with a wall thickness of 0.5mm—such structures would require three-stage processing and welding assembly if using traditional Electrical Discharge Machining (EDM), which not only involves multiple processes but also easily causes deformation due to welding stress. This advantage has also given rise to the concept of “Design for Additive Manufacturing (DfAM).” However, in current practical applications, designers still face tool bottlenecks: for example, although the DfAM module in Autodesk Fusion 360 can optimize structures, the automatic support generation function for complex internal cavities still requires manual adjustment, making it difficult to fully unleash the process potential.

By eliminating the mold development link, RP technology is particularly crucial in the product R&D phase. Taking the automotive industry as an example, the traditional development of door interior panels requires first manufacturing injection molds (taking approximately 3 months and costing over 200,000 RMB) before trial-producing test parts; in contrast, printing the same type of test parts using the FDM process takes only 3 days (including model slicing, printing, and simple polishing), with the ability to modify the 3D model and reprint at any time. In the development of the ET5 model, domestic new energy vehicle startups like NIO used this method to reduce the testing cycle of body cover parts from the traditional 6 months to 4 weeks, thereby shortening the overall vehicle R&D cycle by nearly 1 year.

In small-batch customization scenarios, RP technology demonstrates significant economic advantages. Taking customized control panels in the home appliance industry as an example: for a production volume of 50 pieces, the cost of traditional injection molds is approximately 150,000 RMB, resulting in a mold cost allocation of 3,000 RMB per piece; in contrast, printing via the SLA process requires no mold investment, with a unit cost of approximately 800 RMB, reducing the total cost by over 60%. The medical field provides an even more typical example—the orthopedics team at Beijing Jishuitan Hospital used the SLS process to customize titanium alloy hip prostheses. Compared with traditional standardized prostheses, this not only increased the surgical adaptation rate from 85% to 98% but also reduced the unit manufacturing cost by 40% (mainly by saving labor costs in subsequent polishing and adaptation processes).

Relying on 3D scanning and CAD reconstruction technologies, RP enables the rapid replication of spare parts for aging equipment. For example, when Shenyang Machine Tool repaired the headstock of a CA6140 conventional lathe, it first used a Faro Focus S70 3D scanner to acquire the external data of the headstock (with a scanning precision of ±0.1mm), processed the data using Geomagic Design X software to generate a CAD model, then sintered a nylon prototype via the SLS process to verify assembly precision, and finally manufactured metal spare parts based on the prototype—this entire process took only 10 days, compared to the traditional “mapping-drafting-processing” workflow which requires over 1 month.

Typical Application Scenarios: From Laboratory to Industrial Frontlines

Beyond manufacturing test parts in the R&D phase, the application of RP technology in flexible tooling for mass production is also maturing. For example, in the battery pack assembly of the XPeng G9 model, XPeng Motors used 3D-printed polymer flexible tooling (e.g., positioning jigs, protective bushings) to replace traditional metal tooling—this flexible tooling is lightweight (60% lighter than metal tooling), can be quickly redesigned according to battery pack models, and reduces the unit manufacturing cost from 2,000 RMB (for metal tooling) to 800 RMB, demonstrating significant total cost advantages in small-batch (fewer than 100 sets) production.

In the field of dental healthcare, personalized denture bases manufactured via the SLA process have become a standard solution. Clinical data from the Stomatology Department of Shanghai Ninth People’s Hospital shows that by acquiring patients’ alveolar bone data through oral scanning, the resin bases printed via the SLA process have a 30% higher fit with patients’ alveolar bones compared to traditionally handcrafted bases. This significantly reduces the initial foreign body sensation experienced by patients and decreases the average number of adaptation adjustments from 2 to 1. In the orthopedic field, titanium alloy bone implants (e.g., spinal fusion cages) produced via the SLS process feature a porous structure with a porosity of 60%-70%, which promotes bone cell ingrowth and shortens the post-operative osseointegration time by 40% compared to solid implants.

The aerospace industry’s demand for lightweight and high-precision components is highly aligned with RP technology. For example, in the R&D of the C919 large jetliner, Commercial Aircraft Corporation of China (COMAC) used the SLS process to manufacture nylon brackets inside the cabin—these brackets, designed via topology optimization, are 30% lighter than traditional aluminum alloy brackets while still meeting the cabin load requirements (tensile strength ≥50MPa). Additionally, they can integrate pipeline channels that are difficult to achieve with traditional processes, reducing assembly procedures. In the precision instrument field, optical components (e.g., small lens brackets) manufactured via the SLA process can achieve a surface roughness of less than Ra 3.2μm, meeting the basic requirements for surface flatness in optical testing and reducing costs by 50% when replacing traditionally machined parts.

Existing Challenges: Core Barriers to Technology Popularization

Despite significant improvements in the precision of industrial-grade RP equipment, there remains a clear gap compared to traditional precision machining. For example, when printing a 500mm-long nylon part via the SLS process, the dimensional deviation of parts within the same batch is usually 0.12-0.15mm, while the deviation of the same type of parts processed via traditional CNC grinding can be controlled within ±0.01mm, making it difficult to meet the precision requirements for core components of aero-engines. More critically, there is an issue of process repeatability: tests conducted by an aerospace supporting enterprise showed that when the same SLS equipment prints identical parts at different times (with a 1-month interval), the deviation in tensile strength can reach 8%-10%, which significantly impacts the manufacturing of structural parts requiring stable performance.

Equipment and material costs remain major constraints. Industrial-grade SLS equipment such as the EOS M 400-4 costs approximately 6 million RMB per unit, while the cost of specialized nylon powder (e.g., EOS PA2200) is around 2,200 RMB/kg—more than 14 times higher than that of traditional PP plastic (approximately 150 RMB/kg). In terms of efficiency, the printing speed of medium-sized parts is generally low: for example, printing a 200×150×100mm plastic housing takes approximately 8 hours via the FDM process (speed ~37.5cm³/h) and 6 hours via the SLS process (speed ~50cm³/h), which is far lower than the minute-level per-part production efficiency of traditional injection molding processes, making it difficult to meet the needs of large-scale mass production.

Existing printing materials still have shortcomings in long-term service performance. ABS parts printed via the FDM process have a tensile strength of approximately 30MPa (tested in accordance with ASTM D638 standards), which is only 70% of that of traditionally injection-molded ABS parts (approximately 43MPa). Additionally, they are prone to deformation in environments above 80℃, making them unsuitable for high-temperature scenarios around automotive engines. SLA resin parts have poor aging resistance: Accura 60 resin printed parts from 3D Systems show a color yellowing rate of approximately 15% and a 12% decrease in tensile strength after 6 months of exposure to outdoor ultraviolet radiation, limiting their application in outdoor products. For metal materials, Ti-6Al-4V parts sintered via the SLS process typically have a density of 92%-94%, lower than the 99%+ density of forged parts, and their fatigue life is only 60%-70% that of forged parts, making them unsuitable for load-bearing structures.

Future Trends: Three Directions for Technological Breakthroughs

Based on current R&D progress, precision improvement mainly relies on “hardware optimization + software closed-loop control”: in terms of hardware, dual-laser positioning systems (e.g., 532nm wavelength semiconductor lasers) are used to enhance scanning precision; in terms of software, real-time contour detection cameras feed back dimensional deviations to automatically adjust printing parameters (e.g., laser power, scanning speed). Test equipment from the Fraunhofer IPT Institute (Germany) has achieved a printing precision of ±0.08mm, with expectations of breaking through ±0.05mm within 5 years. In terms of hybrid manufacturing, “additive + subtractive” integrated equipment is gradually being implemented—for example, the LASERTEC 65 3D from DMG MORI can first form part blanks via Laser Metal Deposition (LMD) and then directly perform milling and finishing, avoiding errors caused by secondary clamping of parts and has been applied in mold repair (e.g., repairing worn cavities of injection molds).

In the field of materials, the focus is on the industrialization of high-performance materials: metal matrix composites such as aluminum-based silicon carbide (Al/SiC) have been applied in small-batch 3D printing, with a thermal conductivity 40% higher than that of pure aluminum, making them suitable for manufacturing automotive motor housings; high-temperature resistant resins such as Victrex PEEK 450G have a heat distortion temperature of 310℃ after 3D printing, enabling them to replace some metal parts in high-temperature scenarios. In terms of equipment, modular design has become a trend—for example, the F123 series from Stratasys can print different filaments (ABS, PC, PEKK) by replacing nozzle modules, reducing equipment investment costs for enterprises; large-scale equipment such as the BigRep PRO has a printing size of 1000×1000×1000mm, enabling direct manufacturing of large plastic structural parts (e.g., logistics pallet molds) and reducing assembly procedures.

The core of intelligence lies in the autonomous optimization of process parameters: machine learning algorithms (e.g., random forest algorithms) are used to analyze historical printing data (e.g., the relationship between laser power/layer thickness and part strength), predict potential defects (e.g., warping, porosity), and automatically adjust parameters. Practice at a 3D printing enterprise showed that after adopting this technology, the part qualification rate increased from 82% to 95%, and process debugging time was reduced by 60%. In terms of ecological collaboration, the integration of RP technology with digital twins is deepening—BMW integrated real-time 3D printing data (e.g., temperature, layer thickness) into the digital twin model during the manufacturing of body components for the iX model, simulating the performance of parts after forming to identify potential issues (e.g., internal stress concentration in advance) and realize a closed loop of “design-printing-verification.”

Conclusion

After more than 40 years of development, rapid prototyping technology has transformed from a laboratory tool into an important support for industrial upgrading. However, technology implementation still needs to align with specific industry needs: the medical field requires breakthroughs in the long-term stability of biocompatible materials, the automotive industry needs to address efficiency bottlenecks in mass production, and the aerospace industry must improve the fatigue life of metal parts. In the future, with collaborative breakthroughs in materials, equipment, and software, RP technology is expected to find a balance between “small-batch customization” and “high-performance manufacturing,” truly realizing the leap from “prototype verification” to “mass production” and becoming a core technology in the digital transformation of the manufacturing industry.