In the dynamic realm of modern manufacturing, Swiss screw machining stands as a paragon of precision engineering. At JXD Machining, we’ve harnessed the power of this advanced technology to craft metal and plastic components that not only meet but exceed the most demanding specifications. Our meticulously programmed CNC Swiss Screw machines and automatic lathes serve as the backbone of our operations, ensuring that each part we produce is a testament to quality and accuracy.

Swiss screw machining isn’t just about precision—it’s a game-changer in terms of efficiency, too. For manufacturers, the ability to produce intricate, complex parts rapidly and cost-effectively is invaluable. Thanks to the tight tolerances and high production capabilities of Swiss screw machines, they’ve become the go-to choice across diverse industries. Whether you’re in need of a minuscule, highly detailed component for a state-of-the-art medical device or a robust part for an aerospace application, our Swiss machining technology at JXD Machining delivers high-accuracy results with minimal downtime.

In this comprehensive guide, we’ll take you on an in-depth journey through Swiss screw machining. We’ll demystify how these remarkable machines work, explore the myriad benefits they offer, and showcase the wide-ranging applications of CNC Swiss machined parts. By the end, you’ll have a thorough understanding of why Swiss screw machining is a top choice for countless manufacturing needs and how JXD Machining can be your trusted partner in bringing your projects to life.

How Does a CNC Swiss Screw Machine Work?

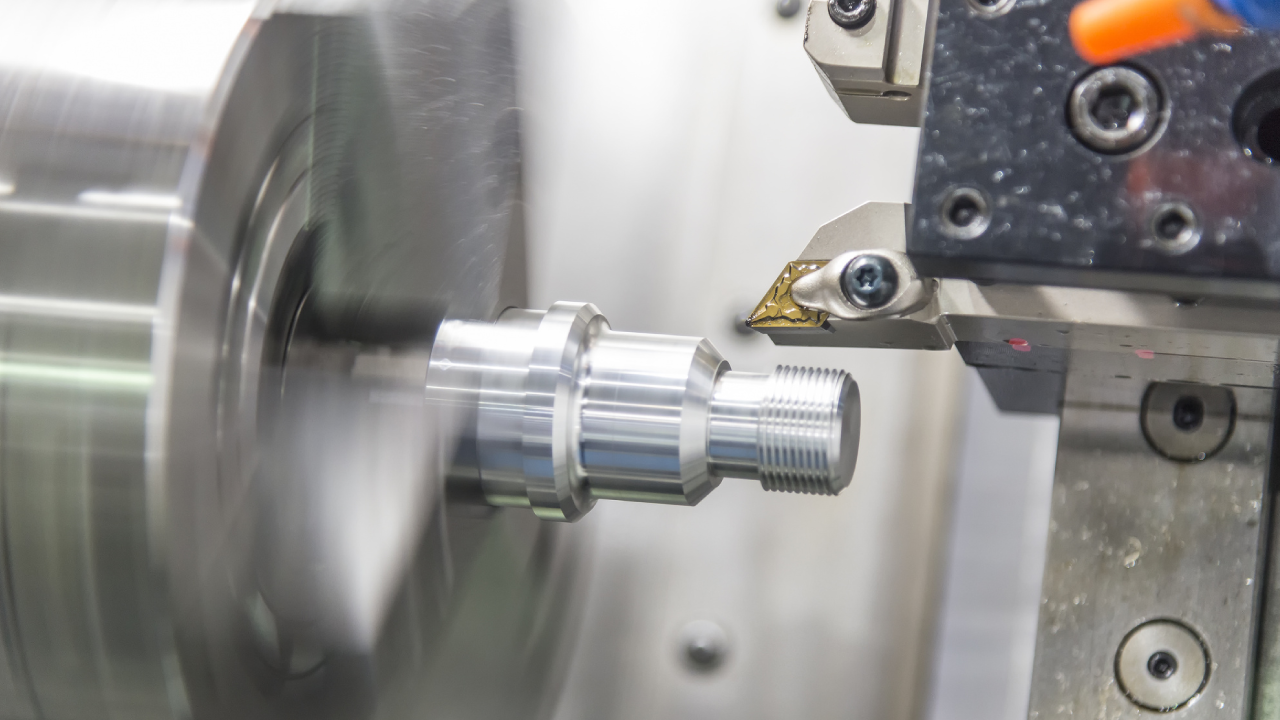

CNC Swiss screw machines operate on a principle that sets them distinctly apart from traditional lathes, making them a marvel of modern manufacturing. Central to their functionality is the seamless collaboration between a turning headstock and a guide bushing. This dynamic duo provides unparalleled stability for bar stocks during the machining process. As the bar stock is fed through the machine, the guide bushing acts like a steadfast anchor, keeping it firmly in place. This minimizes vibrations, enabling the machine to execute extremely precise cuts and drills with remarkable consistency.

The machining process kicks off with programming the component’s design into the machine using advanced CNC controls. This initial step is crucial, as it dictates every detail of the final product—the exact dimensions, the shape, and the features that need to be cut or drilled into the raw material. Once the design is inputted with precision, a bar stock is loaded into the feeder. Our bar feeders at JXD Machining are engineered for efficiency, capable of holding a substantial amount of bar stock. This allows the machine to run continuously for extended periods, making it a perfect fit for large-scale projects. With reduced need for frequent operator intervention, production can proceed smoothly and at a rapid pace.

As the bar feeder advances the rotary cylindrical bar stock through the collet, which securely holds the material in place, the revolving chuck springs into action. It grabs the raw material and pulls it out to the desired product length. The collet then firmly grips the part, keeping it steady and stable while the machining operations take place. To further enhance the precision of the process, a guide brush can be utilized to reduce the gap between the cutting tools and the main spindle. Once the part is fully machined to perfection, it breaks off from the bar stock. Immediately after, the bar feeder pushes the remaining material forward, ready to start the machining of the next component, ensuring a seamless, continuous production flow.

Benefits of Swiss Screw Machining

Higher Production Efficiency

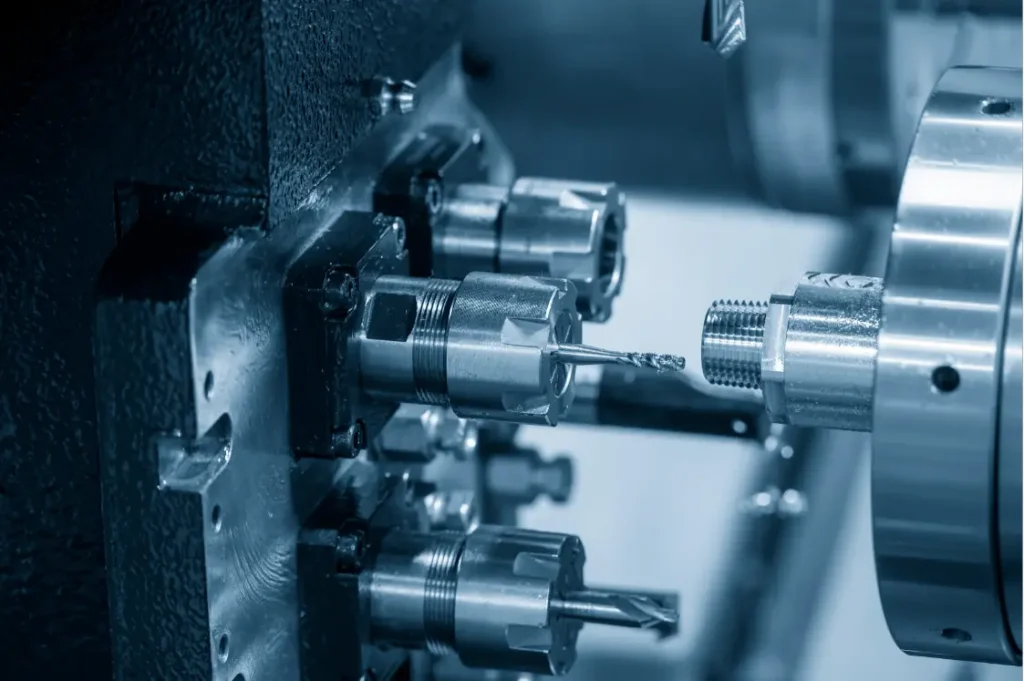

One of the most significant advantages of Swiss screw machining is its remarkable ability to supercharge production efficiency, and at JXD Machining, we’ve witnessed firsthand the transformative impact it can have. Our Swiss screw machines are capable of operating on thousands of parts simultaneously, all with minimal human labor involved. Multi-spindle Swiss screw machines, in particular, are true workhorses in our facility. Designed to execute multiple cuts, slots, and drills at the same time, the spindle rotates with precision, adding features to each part in rapid succession. This eliminates the need for time-consuming secondary operations. For instance, our typical multi-spindle machine, equipped with six primary spindles, can work on six different parts at once. In the time it would take a traditional machine to complete a single part, our Swiss screw machine can churn out six, significantly ramping up output and helping our clients meet tight deadlines.

Moreover, these machines are programmed with meticulous part specifications, enabling them to function autonomously for extended hours. They can run for more than 12 hours without continuous monitoring, making them an ideal choice for large-volume projects. This not only accelerates production but also leads to substantial savings in labor costs, making Swiss screw machining a cost-effective solution for manufacturers looking to scale up their operations.

Diversity of Material

Swiss screw machining is renowned for its versatility when it comes to materials, and at JXD Machining, we take full advantage of this flexibility. We work with an extensive range of CNC machining materials, catering to a wide variety of project requirements. When it comes to metals, we handle various grades, including copper, aluminum, stainless steel, carbon steel, brass, and titanium. Each of these metals has its own unique set of properties that make it suitable for different applications. For example, aluminum’s lightweight nature and excellent corrosion resistance make it a popular choice for parts in the aerospace and automotive industries, where reducing weight without sacrificing strength is crucial. On the other hand, titanium’s high strength and biocompatibility make it the material of choice for medical implants, where durability and safety are of utmost importance.

In addition to metals, Swiss screw machining also works seamlessly with plastics, both thermosets and thermoplastics. This broad material compatibility allows us to create a diverse range of parts with high precision, regardless of the material used. Whether it’s a complex metal component for an industrial application or a delicate plastic part for an electronic device, our Swiss screw machines have the capability to handle the job with ease and excellence.

Flexibility

The Swiss turning process, as practiced at JXD Machining, offers unparalleled flexibility in manufacturing. It has the capacity to produce both small and large precision parts, each with exceptional qualities such as low deflection and high tolerances. The wide range of materials it can work with, spanning both metal and non-metal materials, further enhances this flexibility.

This means that we can meet the unique and specific requirements of our clients with pinpoint accuracy. Unlike conventional manufacturing methods, the Swiss machining process allows us to create custom parts that are tailored exactly to the client’s vision. Whether it’s a part with intricate, detailed designs or one that demands extremely tight tolerances, we have the expertise and the technology to produce high-quality components that not only meet but exceed customer expectations, providing solutions that are truly one-of-a-kind.

Cost-Effectiveness

CNC Swiss lathe machining, as offered by JXD Machining, presents an excellent option for producing thousands of identical parts at a remarkably low cost. This manufacturing technique is especially well-suited for industries that require parts with extreme precision while also keeping a close eye on production costs. Sectors such as aerospace, automotive, medical, and defense have greatly benefited from the cost-effectiveness of Swiss screw machining.

By leveraging advanced machinery and streamlined, efficient processes, we’re able to produce high-quality parts in large quantities without compromising on quality. This not only helps our clients save significantly on production costs but also gives them a competitive edge in the market, allowing them to offer their products at more attractive prices while maintaining superior quality standards.

Faster Production of Machined Parts

In today’s fast-paced business environment, where time is of the essence, the ability to produce parts quickly can make all the difference. Swiss screw machines, as utilized by JXD Machining, are designed with speed in mind, enabling us to create parts rapidly to meet the ever-growing demands of various industries. The ability to accelerate the production process means that we can get parts to market faster, giving our clients a head start in a competitive marketplace.

Parts machined using the Swiss screw machining method are celebrated for their outstanding precision and accuracy. This often eliminates the need for additional post-processing, saving both time and resources. Whether it’s a rush order for a new product launch or a regular production run, our Swiss screw machines ensure that parts are produced quickly and to the highest standards, helping our clients stay ahead of the curve.

High Precision

Precision is the cornerstone of Swiss screw machining, and at JXD Machining, we’ve mastered the art of achieving unparalleled accuracy. Our Swiss screw machines are capable of making highly precise cuts and drills on parts, thanks in large part to the crucial role played by the guide bushing. During the machining process, the guide bushing firmly supports the parts, minimizing any potential movement or vibration. Our CNC Swiss screw machines can rotate parts at speeds of up to 10,000 RPM, enabling us to fabricate parts within an incredibly close tolerance of 0.0002 inches (0.005mm).

This level of precision makes Swiss screw machining one of the most reliable processes for machining small parts that are prone to vibration during traditional machining operations. Whether it’s a tiny, intricate component for a luxury watch or a critical part for a life-saving medical device, our machines can produce parts with the utmost precision, ensuring that every component meets the strictest quality standards.

Reduced Waste

CNC Swiss automated machining, as implemented by JXD Machining, is not only about producing high-quality parts but also about minimizing environmental impact and cost through waste reduction. Although it’s a subtractive manufacturing process, we’ve implemented comprehensive systems to collect scrap metals and recycle them, giving new life to materials that would otherwise be discarded. Our Swiss screw machines themselves contribute significantly to waste reduction by ensuring high precision in machining. With their advanced technology and precise operation, there’s less room for error, resulting in a significant reduction in the number of defective parts.

This commitment to waste reduction not only makes our manufacturing processes more environmentally friendly but also leads to long-term cost savings. By maximizing the use of raw materials, we can offer our clients more cost-effective solutions without compromising on the quality of our products, striking the perfect balance between sustainability and profitability.

Applications of Swiss Screw Machined Parts

Aerospace

The aerospace industry is renowned for its stringent requirements when it comes to component precision and tolerances, and at JXD Machining, we’re up to the challenge. Our CNC Swiss screw machines are specifically designed and equipped to handle the exacting demands of the aerospace sector. We can machine stainless steel and other high-performance materials to meet the rigorous secondary processing requirements of this industry.

Our Swiss screw machines are instrumental in creating a wide variety of aircraft parts, including screws, shafts, couplers, flanges, retainer rings, seat frames, and connectors. These parts are the unsung heroes that ensure the safety and efficiency of aircraft. With our extensive expertise in Swiss screw machining, we’re able to provide the aerospace industry with parts that not only meet but surpass the highest quality and safety standards, contributing to the development of reliable and cutting-edge aircraft.

Food Processing

In the food processing industry, quality and safety are non-negotiable. At JXD Machining, we fully understand the importance of meeting and exceeding the strict quality standards set by this industry. Our Swiss screw-machined parts, such as conveyor belts, trays, stainless steel mixers, OEM machines, and motors, play a vital role in food processing facilities.

These parts are manufactured with the highest tolerances and from materials that are specifically approved for food-contact applications. This ensures that the food processing equipment is not only safe and hygienic but also reliable, contributing to the consistent production of high-quality food products. When you choose JXD Machining for your food processing parts, you can have complete confidence in the integrity and quality of the components we provide.

Military

The military sector demands machined parts that are not only durable but also capable of meeting the highest tolerances, and our Swiss screw machining process at JXD Machining is perfectly suited to this task. We’re proud to produce parts for fighter aircraft, artillery, military ships, and missiles, all of which need to withstand the harshest conditions and perform flawlessly when it matters most.

Our expertise in Swiss screw machining allows us to create parts with the precision and durability required by the military, ensuring the effectiveness and reliability of military equipment. Whether it’s a component for a high-speed fighter jet or a part for a heavy-duty military vehicle, we approach each project with the utmost care and attention to detail, delivering parts that can be trusted in the most challenging environments.

Electrical and Electronics

The electronics industry is constantly evolving, with an ever-increasing demand for parts that feature tight tolerances and complex specifications. At JXD Machining, our Swiss automated machining services have become the go-to solution for many of the challenges faced by this industry.

We produce a wide range of components for circuit boards, radios, connectors, and motherboards. By leveraging the capabilities of Swiss screw machining, we help electronics companies enhance the quality of their parts while simultaneously reducing production costs and time. The high precision of our Swiss screw machines allows us to create parts that meet the exacting standards of the electronics industry, enabling our clients to stay at the forefront of technological innovation.

Medical and Dental

The medical and dental industries rely heavily on high-quality, precision-made components, and at JXD Machining, we’re committed to delivering parts that make a difference in patient care. Our Swiss screw machining method is utilized to produce a diverse range of medical devices and surgical and dental tools. We create components from FDA-approved materials, such as stainless steel surgical instruments, ensuring the safety and reliability of our products.

Our Swiss-machined medical equipment, including CT scanners, ultrasound machines, catheters, litigation devices, and handheld surgical tools, plays a crucial role in saving lives and improving the quality of life of patients. The high-quality components we produce also instill confidence in doctors, dentists, and other medical practitioners, making us a trusted partner in the medical and dental fields. When it comes to precision medical machining, JXD Machining is the name you can trust.

Why Choose JXD Machining for Your CNC Swiss Screw Machining Needs?

At JXD Machining, we’re not just another machining service provider—we’re your dedicated partners in bringing your manufacturing visions to life. We combine our extensive machining capabilities with a team of highly skilled technicians who are passionate about precision engineering. Our CNC Swiss screw machines offer tighter tolerances than conventional CNC lathes, enabling us to produce precision components that are truly in a league of their own. With a wide range of machine tools at our disposal, we can manufacture various workpieces from engineering-grade metals and plastics, catering to a diverse range of project requirements.

Quality is at the heart of everything we do, which is why we’ve invested in modern automated quality assurance equipment, integrated with the latest software system. This advanced setup allows us to measure the inner and external qualities of our machine parts with pinpoint accuracy, ensuring that every part that leaves our facility meets the highest quality standards. Our experts possess in-depth knowledge and years of hands-on experience in Swiss screw machining, guaranteeing that every project is handled with the utmost professionalism and expertise.

Our Swiss screw machine tooling is optimized for efficiency, making it highly suitable for manufacturing parts in quantities ranging from 500 to 50,000 units. In addition, we offer a comprehensive array of secondary services that ensure machined parts have the desired surface finishes, adding the final touches to make your components truly exceptional.

If you’re searching for a reliable, experienced, and customer-focused partner for your CNC Swiss screw machining projects, look no further than JXD Machining. Contact us today, and let our expert team turn your design ideas into high-quality, precision-made reality.