They find extensive use in mechanically fastened parts across diverse industries, including medical, electronics, automotive, and consumer goods. Their popularity stems from their versatility and ease of use. However, to create accurate threaded holes for your products, a comprehensive understanding of hole threading is essential.

In this article, we at will explain threaded holes, their types, the production process, and how they differ from tapped holes. Read on to discover best practices for successful hole threading!

What Are Threaded Holes?

Threaded holes are circular openings featuring internal threads. At JXD Machining, we produce these threads through tapping or other threading methods, as there are multiple techniques available. Machinists typically employ a cutting tap to create these threads within the internal diameter of a pre-drilled hole. These threaded holes function as non-permanent joints, providing a secure location for fastener installation in mechanical assemblies.

Tapped or threaded components are designed to fit a threaded shaft, such as metal and machine screws, ensuring a reliable connection. The threads generate resistance, preventing the fastener from loosening over time. Additionally, they allow for easy removal of the fastener when necessary.

Types of Threaded Holes

·Through Holes

·Blind Holes

Through Holes & Blind Holes

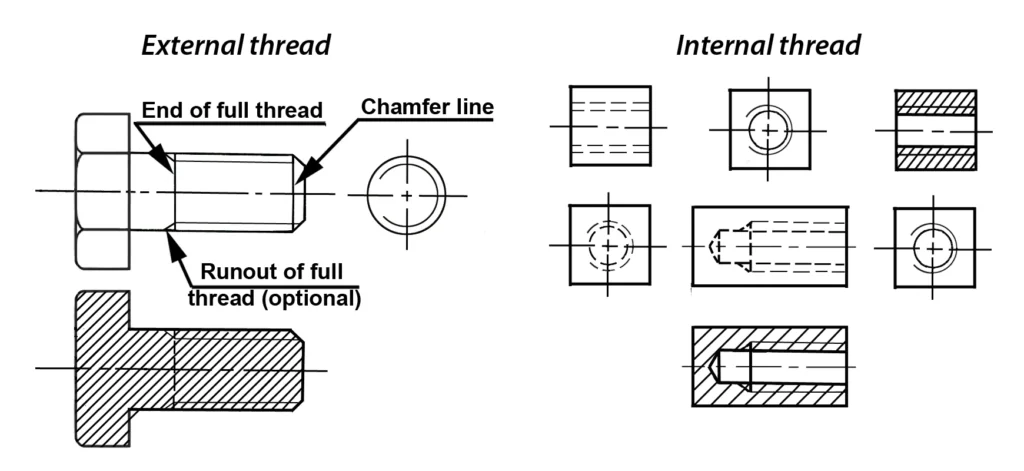

Threaded holes can be classified into two main categories based on hole depth and opening, as recognized by JXD Machining:

Blind Holes: These holes do not penetrate entirely through the drilled part. They are characterized by their thread size and hole depth. When using a conventional drill, blind holes often have a conical bottom, while an end mill results in a flat bottom.

Through Holes: These holes pass completely through the workpiece from one end to the other, leaving the workpiece with two openings on opposite sides.

How To Make Threaded Holes

Creating threads in holes demands technical expertise and the right tools, which JXD Machining has in abundance. Here are the simple steps involved in producing precise internal threads in machined parts:

1、Cut a Cored Hole: The initial step in hole threading is to create a hole for the thread using a CNC twist drill to achieve the desired hole diameter. It’s crucial to use the appropriate drill to ensure accurate hole cutting in terms of diameter and depth. At JXD Machining, we recommend applying a cutting spray to the drilling tool before cutting the hole to enhance the surface finish.

2、Chamfer the Hole: To chamfer a hole, a drill bit is slowly moved in the chuck until it reaches the hole’s edge. Chamfering ensures proper alignment of the screw threads, preventing raised burrs and extending the tool’s lifespan.

3、Straighten the Hole by Drilling: A motor and drill are needed to straighten the drilled hole. When creating a threaded hole, it’s important to consider the hole and bolt sizes. The bolt diameter typically determines the hole size before tapping. Usually, the bolt diameter is larger than the drilled hole as tapping increases the hole size. Additionally, pay attention to the hole depth to avoid creating a through-threaded hole when aiming for a blind hole. The type of tap used also influences the hole depth. For example, a taper tap doesn’t create full threads and is suitable for deep holes.

4、Tap the Drilled Hole: Tapping creates internal threads in a hole for a perfect fastener fit. When tapping a drilled hole, the tapping tool is turned clockwise. Machining experts, like those at JXD Machining, recommend making a 180º anticlockwise rotation for every 360º clockwise rotation to prevent metal shavings from accumulating and to allow for proper cutting of the tapping tool’s teeth.

Types of Taps Used in Hole Threading

Machinists at JXD Machining commonly use three main types of taps for creating threads in holes of machined parts:

·Taper Taps: Ideal for creating threads in harder materials due to their high strength and cutting pressure. Taper taps have six to seven cutting teeth that start taping from the tip. They feature a conical tip with a slight angle to the threads, making it easier to initiate hole threading compared to a bottom tap. However, the first ten threads made with taper taps may not be fully formed, so finishing threading with this type of tap is not recommended. Taper taps are also unsuitable for very hard materials or holes with a large diameter.

·Plug Tap: Well-suited for creating deep and thorough threaded holes. It gradually cuts the internal thread in a workpiece using a progressive cutting motion. Machinists often use it after the taper tap, so it’s commonly referred to as the “second tap.” Plug taps are useful for correcting threads that require minor adjustments. However, experts advise against using them when the drilled hole is close to the edge of the workpiece, as the cutting teeth can cause breakage when reaching the edge. They are also not suitable for very small holes as the tap may break.

·Bottoming Tap: This type of tap has one or two cutting teeth at its start. The bottom tap is ideal for threading deeper holes, and its use is often determined by the desired hole length. It threads holes from the bottom when there is insufficient space to start from the top. With a bottom tap, it’s easy to cut threads down to the bottom of a through hole, and it’s also suitable for threading a shallow blind hole. Machinists typically begin threading a hole with a taper or plug tap and finish with a bottoming tap for accurate threading. However, bottom taps are not available in all sizes as they are specialized tools.

Threaded Holes Vs. Tapped Holes: Their Differences

Threaded holes and tapped holes are common concepts in mechanical assemblies. A threaded hole is a general term for a hole with threads on its inner walls. Since cutting taps can create these threads, the terms “threaded hole” and “tapped hole” are sometimes used interchangeably. Other methods like thread milling or thread rolling can also create internal threads in a hole. Additionally, the threading process can create threads on the exterior of a hole using a die tool.

However, a tapped hole specifically refers to a threaded hole created in an existing hole through the tapping process. These drilled holes are tapped using either a cutting tap or a forming tap, with the tap creating threads as it turns. There are other ways to create threads in a hole besides cutting, such as forming or rolling threads on the inner diameter.

Here are some additional differences between tapped holes and threaded holes:

·Material: While many engineering materials are suitable for hole threading and tapping, a tapping tool works better with harder materials than threading. With the right tap tool, threads can be created on hardened steel.

·Speed: In terms of operation speed, tapped holes may take longer as different tapping tools are needed to achieve the perfect thread fit for various hole sizes. However, high-speed tapping centers with rigid taps can create threads more quickly than a thread mill.

·Flexibility: Tapping offers less flexibility as the thread fit cannot be altered once the process is complete. Tapped holes typically have fixed locations and sizes after threading. In contrast, threading is more flexible with a wide range of options for altering the thread size.

·Cost: A single thread mill can easily create threads in a hole. Using different tapping tools for a single hole increases tooling costs, which may also rise due to damage. Moreover, a single thread milling tool can efficiently create a variety of hole sizes, significantly reducing tooling costs and time. A thread mill can produce right-hand and left-hand threads, internal and external threads, and large threaded holes.

Helpful Tips to Consider When Making Threaded Holes

At JXD Machining, we recognize that several factors can influence hole threading in parts, such as the properties of the intended material, hole characteristics, and more. Here are some considerations for effective hole threading:

Material’s Hardness: A material’s hardness determines the force required for drilling and tapping. Harder materials demand more force. For example, when threading a hole in hardened steel, a carbide tap is recommended due to its high heat and wear resistance. Applying lubricants to the tap tool eases hole threading and prevents tool and material deformation. When machining hard materials, reducing the cutting speed of the tool minimizes tool wear and ensures better surface quality.

Ensure Optimal Hole Depth: Achieving the desired depth when threading holes, especially in blind tap holes, can be challenging. Blind holes have more restrictions compared to through holes. To avoid over or under – threading, reduce the feed rate or cutting speed to reach the optimal depth.

Maintain Standard Thread Size: The chosen thread size can impact the entire threading process. Standard thread sizes, such as Metric thread (ISO), British standard, or National (American) standard, ensure a perfect fit. The metric thread standard is the most popular, with thread sizes having corresponding diameters and pitches. For example, M6 1.00 has a bolt diameter of 6 mm and a thread pitch of 1.00. Other common metric sizes include M12 1.75 and M10 * 1.50.

Pick Suitable Machinery: Using the right tools is crucial for the success of any machining process. Cutting tools (single lip cutting tool or cutting taps) or forming taps can be used to create a tapped or threaded hole. Although both can create internal threads, their mechanisms differ. The material texture and bolt diameter will determine the choice. Cutting tap tools remove material to create space for the screw thread, while forming taps roll material to produce threads without creating metal shavings. Forming taps are ideal for threading products made from less rigid materials like brass or aluminum.

Proper Positioning: Threading must occur in the correct position for a successful process. The thread can be located anywhere, such as close to the edge or in the middle. However, threading near the edge requires extra care as mistakes can affect the part’s surface finish and damage the tapping tool.

Angled Surfaces: When working with a workpiece having an angled surface, experts recommend carefully sliding the tapping tool down the surface to avoid breakage due to bending stress. For example, when machining parts with angled surfaces, milling a pocket to create a flat surface for the tapping tool is advisable.

Selecting JXD Machining: Your Trusted Partner for Reliable Machining Services

At JXD Machining, we have a range of CNC machines and processes capable of cutting threads in holes. When you need a reliable CNC machining services provider for your CNC parts manufacturing requirements, JXD Machining is your top choice. We are a leading CNC shop with years of experience in manufacturing custom CNC machined parts with tight tolerances in various materials. Our team of engineers and product quality experts can design tapped and threaded holes for your parts precisely according to your design requirements.

As your trusted partner, we offer support and manufacturing solutions to bring your design to life. Submit a CAD file today to receive a free quote. We also provide high – quality design for manufacturability feedback to optimize your parts production. Don’t hesitate to contact us today to discuss the details of your CNC machining project!

Conclusion

Threaded holes are essential elements for fastening, mounting, or joining components in assemblies. However, a solid understanding of the necessary processes and tools is vital for achieving high – quality threading. This article from JXD Machining has provided a detailed overview of all you need to know about hole threading. If you encounter difficulties creating threaded holes in your products, feel free to contact us.

FAQs

1。What Are the Common Complications of Threaded Holes?

Typical problems associated with threaded holes include thread galling, thread stripping, insufficient thread engagement, and cross – threading. To avoid these issues, it’s advisable to follow proper tapping procedures.

2.Can Damaged Threaded Holes be Repaired?

When a threaded hole is damaged, it can be fixed using threaded inserts, helical inserts, or by simply re – tapping it to a larger size.

3.What Material Can be Tapped with Threads?

Various materials can be tapped, including plastic, wood, and metals such as brass, aluminum, and steel. However, soft materials like wood or 3D – printed parts will have more delicate threads. Flexible or thinner sheet metal, like aluminum, requires extra care to prevent damage.