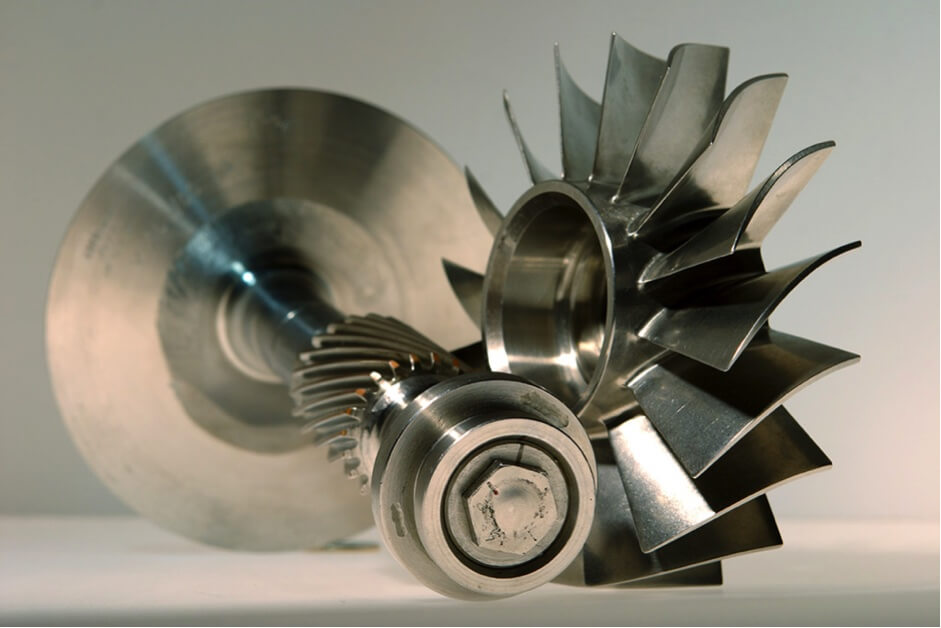

Titanium’s exceptional strength-to-weight ratio and corrosion resistance make it a material of choice for many high-performance products. Designers often specify titanium when they need a lightweight part that still withstands extreme conditions. It is commonly used in aircraft components, medical implants, and defense hardware – for example, titanium parts appear in airplane frames and turbine blades as well as hip or dental implants.

For more on this metal’s properties, see our Materials > Metal Materials > Titanium section, which covers its grades and basic applications.

Machining Challenges: Why Titanium Is Difficult to Cut

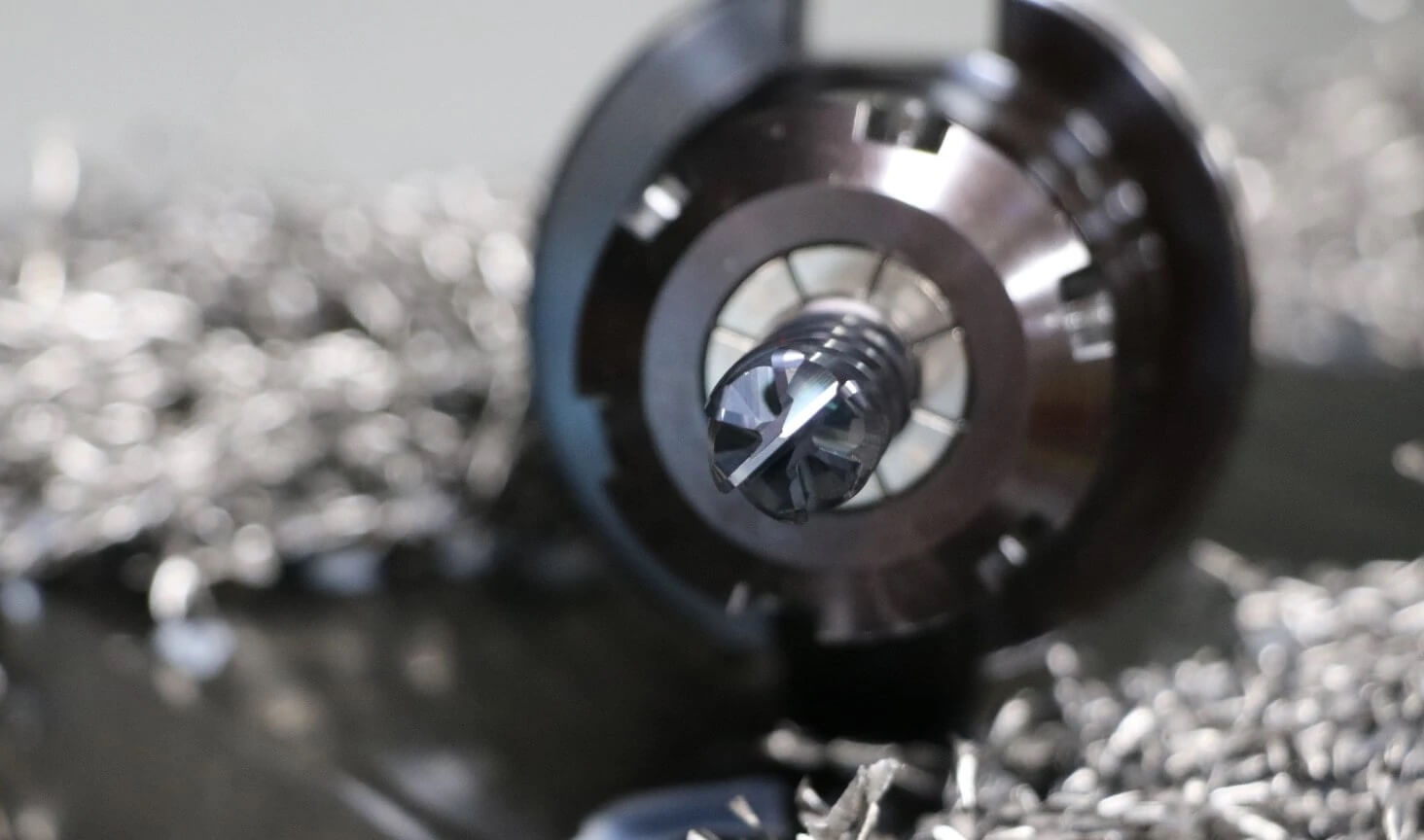

Even with these advantages, machining titanium presents unique challenges. Compared to aluminum or steel, titanium is much harder to cut. Machinists tackle this by slowing feed rates and using heat-resistant tools.

Cutting titanium typically requires:

-

Carbide end mills with specialized coatings

-

Flood coolant or cutting oil to carry away heat and flush chips

-

Rigid clamping and fixtures to reduce deflection

Because titanium has poor thermal conductivity, heat builds up quickly. A high coolant flow helps prevent chip welding and prolongs tool life. Without solid workholding, vibration or part movement can ruin precision and cause tool breakage.

Applications of Titanium CNC Parts

Titanium parts are found in many industries, including:

-

Aerospace & defense: airframe structures, turbine blades

-

Medical: implants, surgical instruments

-

Marine & oil/gas: desalination systems, offshore hardware

-

Automotive & consumer: racing components, premium sporting goods

Each use case shapes design priorities. A jet engine mount must be extremely strong and precision-made, while a hip implant must balance strength with biocompatibility.

Design Considerations for Titanium Parts

To reduce costs and improve manufacturability, engineers should follow design-for-manufacturing (DFM) principles:

-

Avoid complex geometries like deep cavities or sharp internal corners

-

Use generous radii and consistent wall thickness

-

Leverage CAD/CAM simulation to validate toolpaths

-

Design custom jigs and fixtures to minimize flexing

-

Break complex parts into modular machining stages if needed

Well-planned designs result in faster machining, lower tool wear, and more predictable lead times.

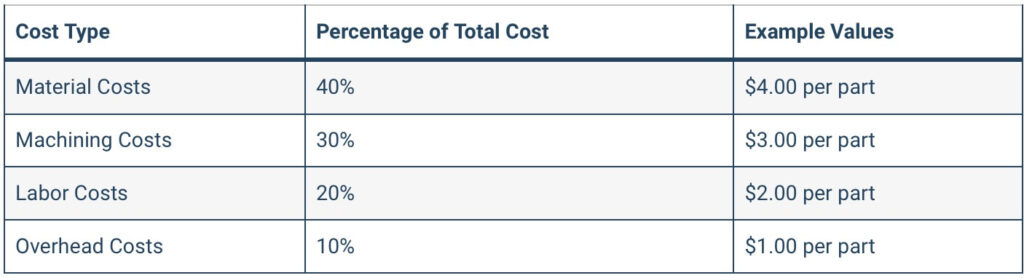

Cost Factors in Titanium CNC Machining

Titanium is significantly more expensive than steel or aluminum, and its machining difficulty increases the overall cost per part.

Key cost drivers include:

-

Slower feed rates, leading to longer production time

-

Higher tool wear, requiring frequent replacement

-

Large volumes of coolant and specialized finishing

-

Higher material costs for premium titanium grades

However, total lifecycle value often offsets the initial cost. Titanium’s durability and performance can reduce long-term maintenance or increase fuel efficiency. For best results, choose the appropriate grade:

-

Grade 5 (Ti-6Al-4V): strongest, best for aerospace

-

Grade 2: best corrosion resistance, ideal for chemical and medical

How to Choose the Right CNC Supplier

Beyond price and lead time, buyers should evaluate supplier expertise and quality systems.

Look for shops that offer:

-

Proven titanium machining experience

-

ISO 9001 (and AS9100 / ISO 13485 if applicable)

-

Multi-axis CNC machines for complex geometries

-

Pre-production DFM support and CAD feedback

-

Precision inspection processes to verify tolerances

A knowledgeable partner will reduce your risk and help optimize the part for both performance and cost.

Conclusion: The Key to Titanium CNC Success

Titanium CNC machining delivers high-performance parts—but only with the right preparation.

To succeed, you need:

-

Smart part design

-

Realistic cost expectations

-

A trusted, capable CNC machining partner

JXD Machining specializes in titanium CNC production. We use multi-axis machining centers, premium cutting tools, and robust quality controls to deliver precision titanium components with speed and reliability.

Contact JXD Machining today to discuss your titanium project. Our team provides design feedback, material advice, and competitive quotes to help bring your vision to life.