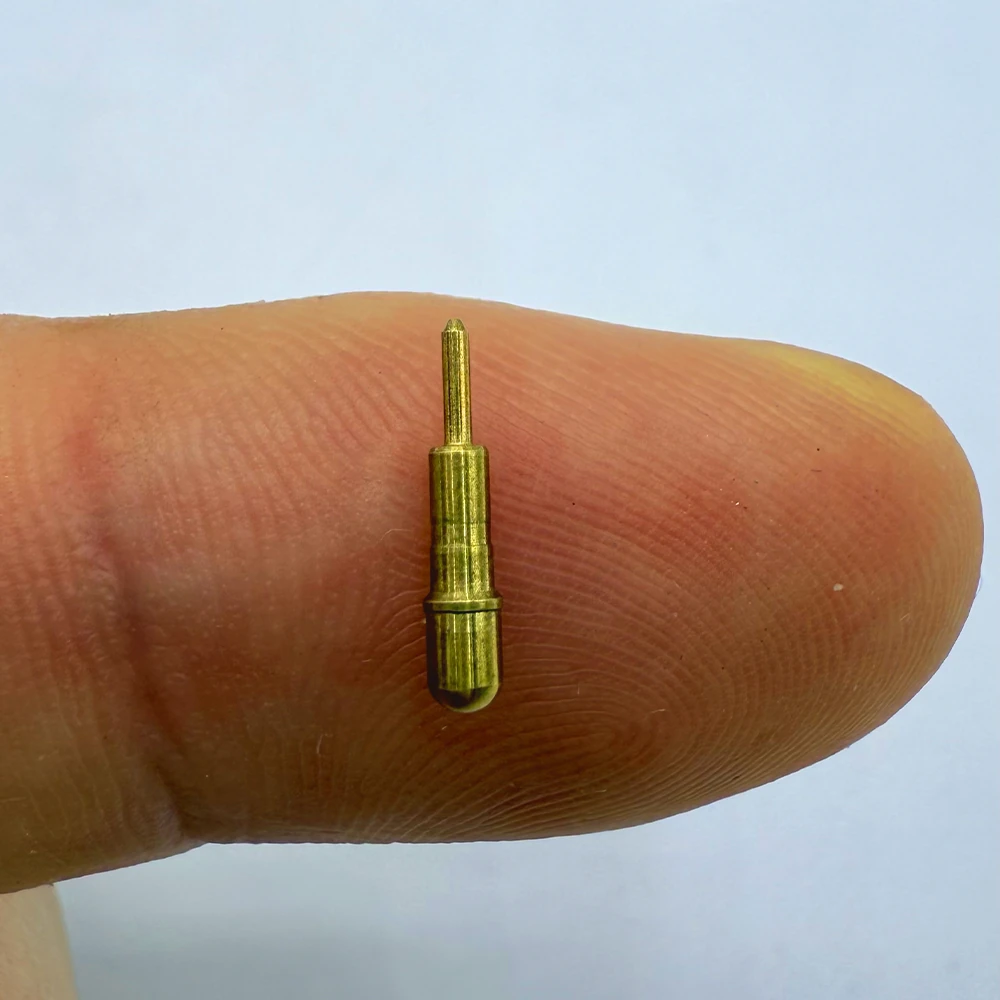

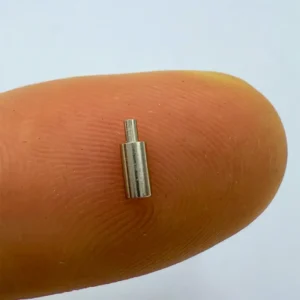

This precision brass turned pin connector is manufactured using advanced Swiss CNC turning technology, ensuring high accuracy within ±0.01mm tolerance. Made from durable brass (C3604 / CuZn39Pb3), it offers excellent conductivity, corrosion resistance, and wear resistance, making it ideal for electronic connectors, micro switches, sensors, communication devices, and precision instruments.

The surface can be customized with gold plating, nickel plating, or tin plating to enhance performance and durability. With flexible MOQ, fast sampling (5-7 days), and stable batch production (2-3 weeks), this micro precision component is widely used in industries such as electronics, medical devices, aerospace, and automotive.

Our factory provides OEM/ODM customization, ensuring that every pin or connector part meets customer-specific drawings and technical requirements.

At JXD Machining, we operate a 5,000+ square meter fully integrated CNC machining facility, armed with a fleet of 40+ advanced pieces of equipment to meet diverse customization demands. Our core equipment lineup includes: 12 sets of 3-axis CNC milling centers (Haas VF-2), 8 sets of 4-axis machining centers (DMG MORI CMX 1100 V), 5 sets of high-precision 5-axis milling centers (MAZAK Variaxis i-700), 10 sets of CNC turning lathes (Okuma LT2000-MY), 3 sets of Swiss-type automatic lathes (Citizen M32), and a complete

Surface Treatment line covering anodizing, sandblasting, and powder coating.

We excel in both flexible rapid prototyping and stable high-volume production: we support 1-50 pieces of rapid sampling and 10,000+ pieces of mass production, with the ability to process over 20

Materials including

Aluminum(6061/7075),

Stainless Steel(304/316),

Titanium alloy (TC4),

Brass, and engineering

Plastics ( POM /

PEEK ). With a strict tolerance control range of ±0.005mm to ±0.05mm, we easily handle complex structures such as deep holes, curved surfaces, and multi-step components, serving key industries like

Electronics, Medical devices,

Consumer Products, and

Industrial Automation.

On delivery efficiency, we balance speed and precision: rapid prototyping takes 3-5 working days, small-batch production (50-500 pieces) is completed in 7-10 working days, and large-volume orders are delivered within 15-25 working days (adjustable based on order scale and complexity).

Want to see our workshop layout, equipment, and production process? Click here for our “About Us” page.

Quality Assurance

At JXD Machining, our strict, streamlined quality & outbound process—backed by advanced tools—guarantees compliance:

Incoming Check: Verify raw material certificates + sample tests (hardness, composition) to rule out defects.

In-Process Inspection: Spot-check critical stages with CMMs to validate tolerances (±0.001mm) early.

100% Final Test: Full dimensional, surface roughness, and functional checks—only passers move forward.

Outbound Review: Secure packaging + batch labeling; test reports/certifications included for traceability.

Every component leaves ready to meet your standards. Learn more & view certificates →

Click here