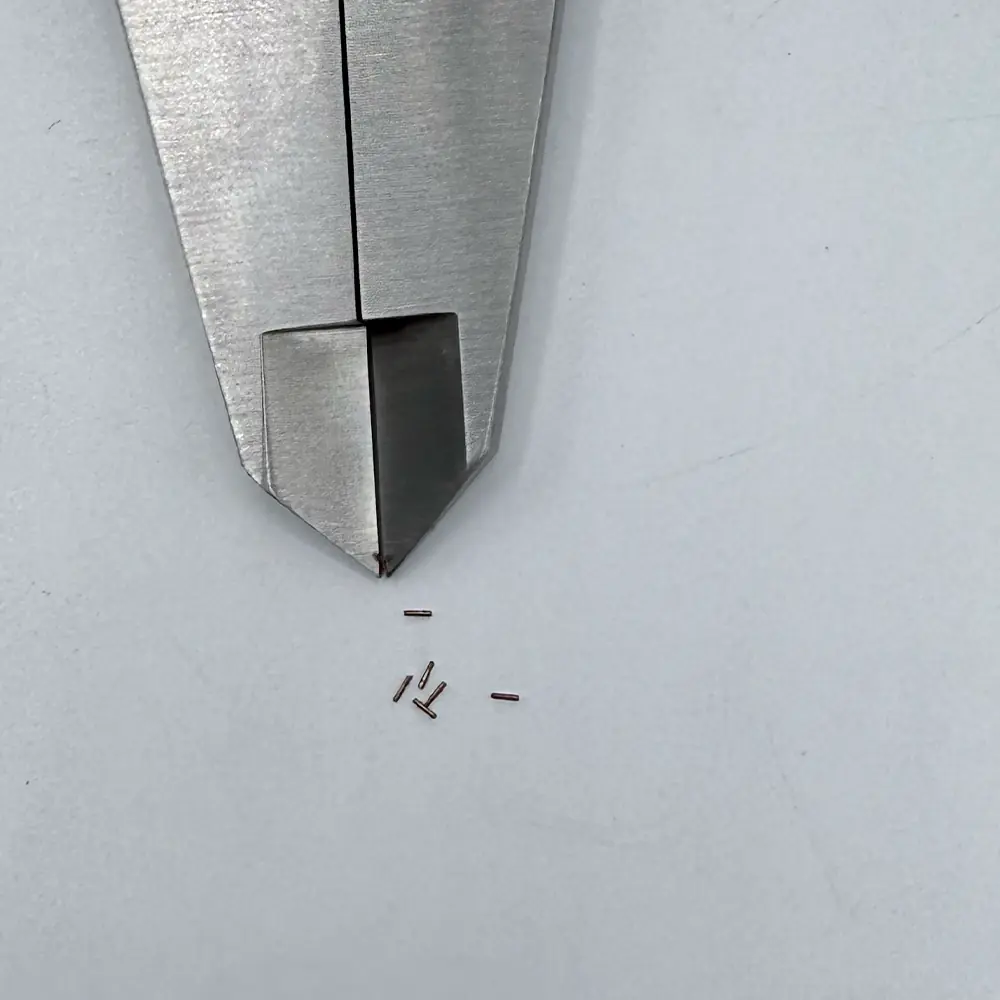

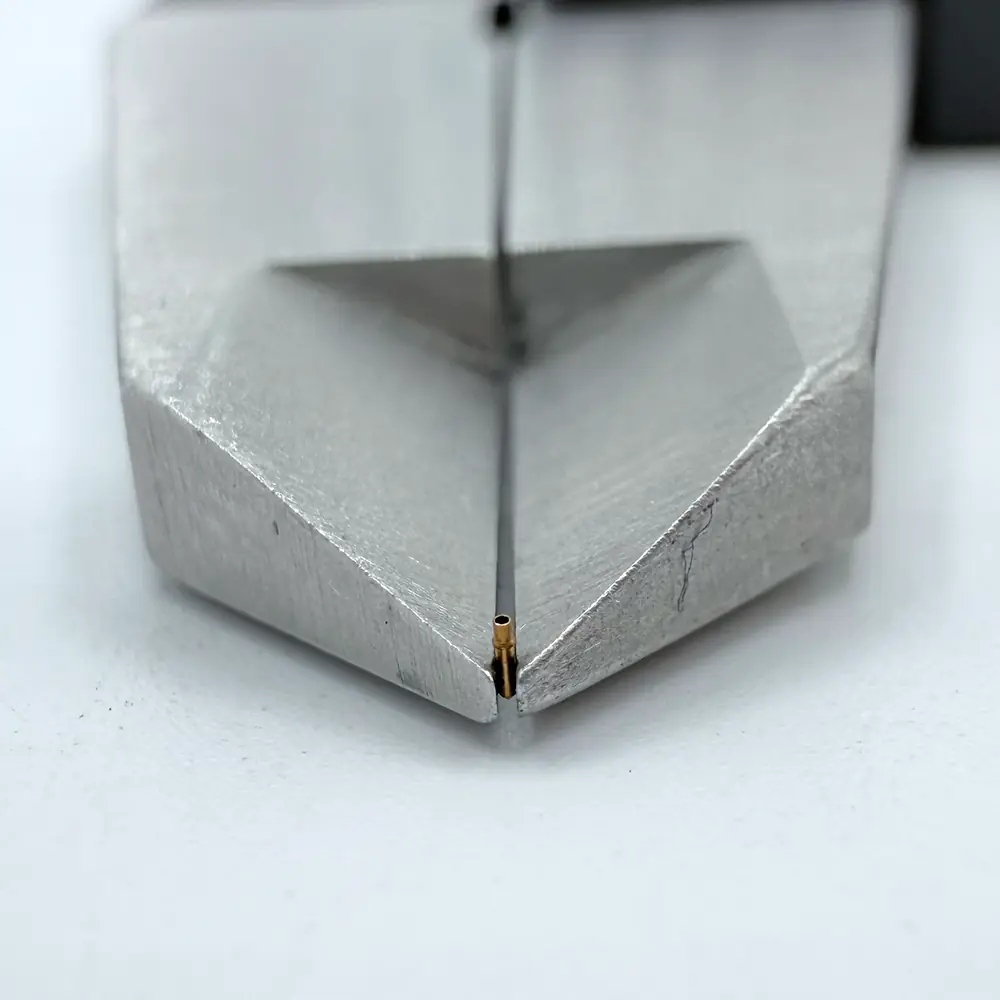

Bunlar İsviçre tipi torna tezgahında işlenmiş ESCO uyumlu hassas parçalar Aşağıdaki içerik Türkçeye çevrilmiştir:

"Yüksek hassasiyetli endüstriyel montaj senaryoları için tasarlanmış ESCO serisi İsviçre torna makineleri aracılığıyla üretilen özel bileşenlerdir. ESCO ekipmanlarının temel aksesuarları olarak, otomotiv şanzıman sistemleri, tıbbi cihaz mekanizmaları ve havacılık küçük bileşen montajı gibi sıkı boyutsal kontrol gerektiren senaryolarında mükemmel bir performans sergilerler."

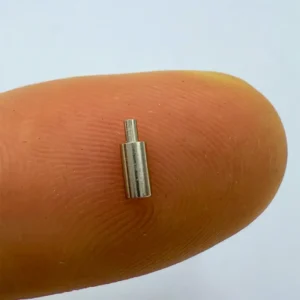

Yüksek kaliteli paslanmaz çelik (304/316) veya alüminyum alaşımdan (6061/7075) üretilen bu parçalar, 5 mm’den 300 mm’ye kadar özelleştirilebilir uzunluklar sunar ve ±0.005 mm’ye kadar tolerans sağlar—ESCO makinelerinin operasyonel standartlarıyla mükemmel uyum sağlar. Pasivasyon ve elektrolizleme gibi yüzey işlemleri, korozyon direncini artırarak, bu parçaların zorlu çalışma ortamlarına (örneğin, nemli endüstriyel atölyeler veya kimyasal işleme alanları) uygun hale gelmesini sağlar.

"Önemli avantajlar şunlardır:" Aşınmaya dayanıklı ESCO hassas bileşenler performans (değiştirme sıklığını azaltma) ve düşük sürtünme yüzeyleri (ekipman operasyon gürültüsünü azaltma). Aşınmış ESCO parçalarını değiştirmek veya modifiye edilmiş ESCO makineleri için yeni bileşenleri özelleştirmek amacıyla, bu parçalar ISO 9001 kalite standartlarına uygundur—her bir birim, tutarlılığı garanti etmek için CMM incelemesinden geçer. Güvenilir ESCO uyumlu işleme çözümleri arayan otomotiv, medikal ve havacılık üreticileri tarafından yaygın olarak benimsenmiştir.

CNC İşleme Tesislerimiz ve Yeteneklerimiz

Atölye düzenimizi, ekipmanlarımızı ve üretim sürecimizi görmek ister misiniz? “Buraya tıklayın.Hakkımızdasayfa

Kalite Güvencesi

Gelen ÇekHammadde sertifikalarını ve örnek testlerini (sertlik, bileşim) kontrol edin, hataları dışlamak için.

Proses İçinde Muayene"Kritik aşamaları CMM'lerle kontrol ederek toleransları (±0.001mm) erken doğrulayın.

0 Final TestTam boyutlu, yüzey pürüzlülüğü ve fonksiyonel kontroller - yalnızca geçenler ilerler.

Dışa Dönük İncelemeGüvenli ambalaj + parti etiketlemesi; izlenebilirlik için test raporları/sertifikalar dahildir.